Abandonment Vent Flow Testing

Under AER directive 20, Surface Solutions performs in-depth gas flow detection that surpasses the mandated “bubble in a cup” vent flow determination. Using patented data-logging technology, we offer our client’s the most accurate measurements of the 10-minute vent flow determination.

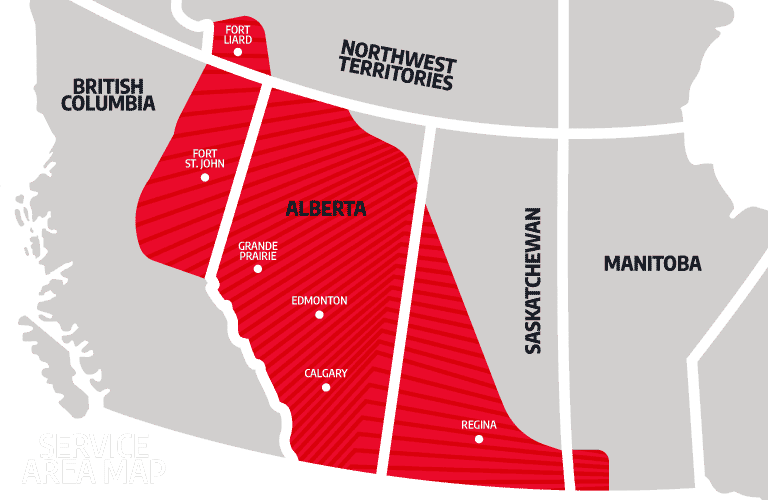

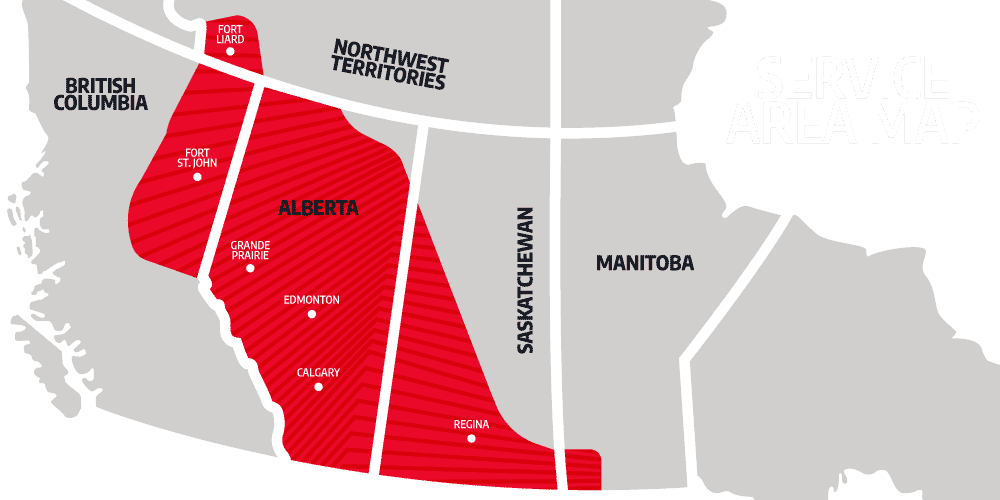

Surface Solutions’ provides on-site well services to deliver strong logistical project performance to maximize efficiency and minimize the risk-averse effects on environmental receptors from drilling waste and gas migration exposure. The Surface Solutions team provides cost-effective results that exceed the highest regulatory compliance, disposal, and monitoring operations in mind across Western Canada.

Surface Solutions’ gas migration(GM) =, including infrared methane detection and digital pressure and temperature logging, to ensure accurate test results and compliance with regulatory requirements. We can complete gas migration assessments year-round due to the non-intrusive technology we use.

Surface Solutions can also perform intrusive testing based on specific government regulations or client preferences. Surface Solutions takes great care to differentiate between true gas migration responses and false positives due to soil contamination or ambient interference, such as wellhead leaks.

The most important factors in a successful well abandonment involve coordinating field operations, including all services and equipment, to increase efficiency and save money.

Surface Solutions provides:

- Groundwater protection and porous zone isolation

- Regulatory applications, waivers, and reporting

- Engineering and geological well file assessments

- Surface casing vent flow testing and gas migration testing

- Gas sampling for carbon isotope source determination

Surface Solutions can pinpoint the source of the gas migration and the concentration of biogenic or thermogenic methane. Extensive experience with risk assessments, carbon isotope analysis, and groundwater protection surveys make our reports critical to proper wellbore remediation. An SCVF test, also called a “Bubble Test,” is used in regions where wells are operated with a surface casing vent in the open position. Fluids entering the annulus escape through the surface casing vent resulting in a surface casing vent flow (SCVF).

Our goal is to eliminate potential liabilities, including surface casing vent flows, gas migrations, groundwater contamination, and soil contamination associated with these non-productive assets.

The well abandonment process can vary depending on different factors, including the diameter of a well, the well casing, the environment, and the condition of the well.

Surface Risk Variables

The location of oil and gas wells being drilled or actively produced is evident, both from the surface and through a notation on the land title. Abandonment of an oil and gas well occurs by rendering the well incapable of flow with a cement plug in each formation the wellbore passes through. Cut and cap is surface abandonment cutting the pipe approximately one meter below the surface and placing a cap over the casing.

Abandoned wells rarely require maintenance, but adequate access to the site needs to be maintained in case it is necessary due to a leak. Repairing an abandoned well usually requires a service rig and, at times, may require a drilling rig which requires a larger work area and access to the abandoned wellbore.

Abandoned Wellbore Safety

An abandoned wellbore is not visible on the surface representing a risk to excavation and construction equipment and the safety of the equipment operator if abandoned wells are not properly located. The risk to public health and safety from an abandoned well is very low.

Problems arise when a reclaimed site is invisible, or its location is unknown. These abandoned wellbores pose a risk to future developers because wellbores are not removed, said a public safety spokesperson for the Energy Resources Conservation Board (ERCB), which regulates the industry’s infrastructure.

Abandoned Oil and Gas Wells

Abandoned oil and gas wells grow annually within Alberta’s energy industry. When a well is abandoned, the company must reclaim the area before it discharges its interest on the surface title. Problems arise when a reclaimed site is invisible, or its location is unknown. These abandoned wells pose a risk to future developers because wellbores are not removed. Should the gas begin to migrate, all development surrounding this well will need to be removed,

Surface Solutions is a unique well abandonment service provider that can abandon wells utilizing the latest cost-effective technology or abandon wells through conventional methods. We strive to deliver cost-effective solutions that reduce ground disturbance protocols, are safer, and reduce environmental impacts to help move sites through the reclamation process faster.

Wells must be tested for gas migration before cut and cap operations. Cut and cap operations must not be conducted until gas migration to the surface around a wellbore has been mitigated. A final test confirming that no gas migration is present is conducted one year before the date of cut and cap.

Directive 20 - Well Abandonment

The Alberta Energy Regulator(AER) Directive 20: Well Abandonment requirements for abandonments, casing removal, zonal abandonments, and plugbacks as mandated in the “Oil and Gas Conservation Rules:.

The purpose of a well abandonment is to cover all non-saline groundwater and to isolate or cover all absorptive zones.

All open and cased-hole abandonments must be conducted following the requirements in this directive.