Emissions

Testing

Surface Solutions Inc. is known for innovative equipment and safe work procedures that help producers comply with AER directive 60.

The industry’s goal is to have the upstream petroleum industry continue to reduce the volume of solution gas routinely flared, incinerated, and vented. Because of this, regulators expect upstream petroleum to pursue continuous improvement in reducing solution gas flaring, incineration, and venting. With technological advances in data acquisition, oil and gas producers are able to have test data that is flexible and affordable. SSI has built a solid foundation for business, based on leadership and excellent customer service.

Planning is key at SSI – by utilizing our database, we save you time and money while managing your complete production testing needs.

Pneumatic Controls Measurement

In accordance to a 2016 methane study, Alberta totaled 1,688 pneumatic devices that were inventoried in a survey of 397 oil and gas wells. SSI applies a unique approach to capturing vented emissions on each well site. Using our vent measurement devices, a strategy is laid out so that the producer gets the most accurate results in determining .17m3 per hour of emitted vent gas.

Read more about our Pneumatic Controls Measurement.

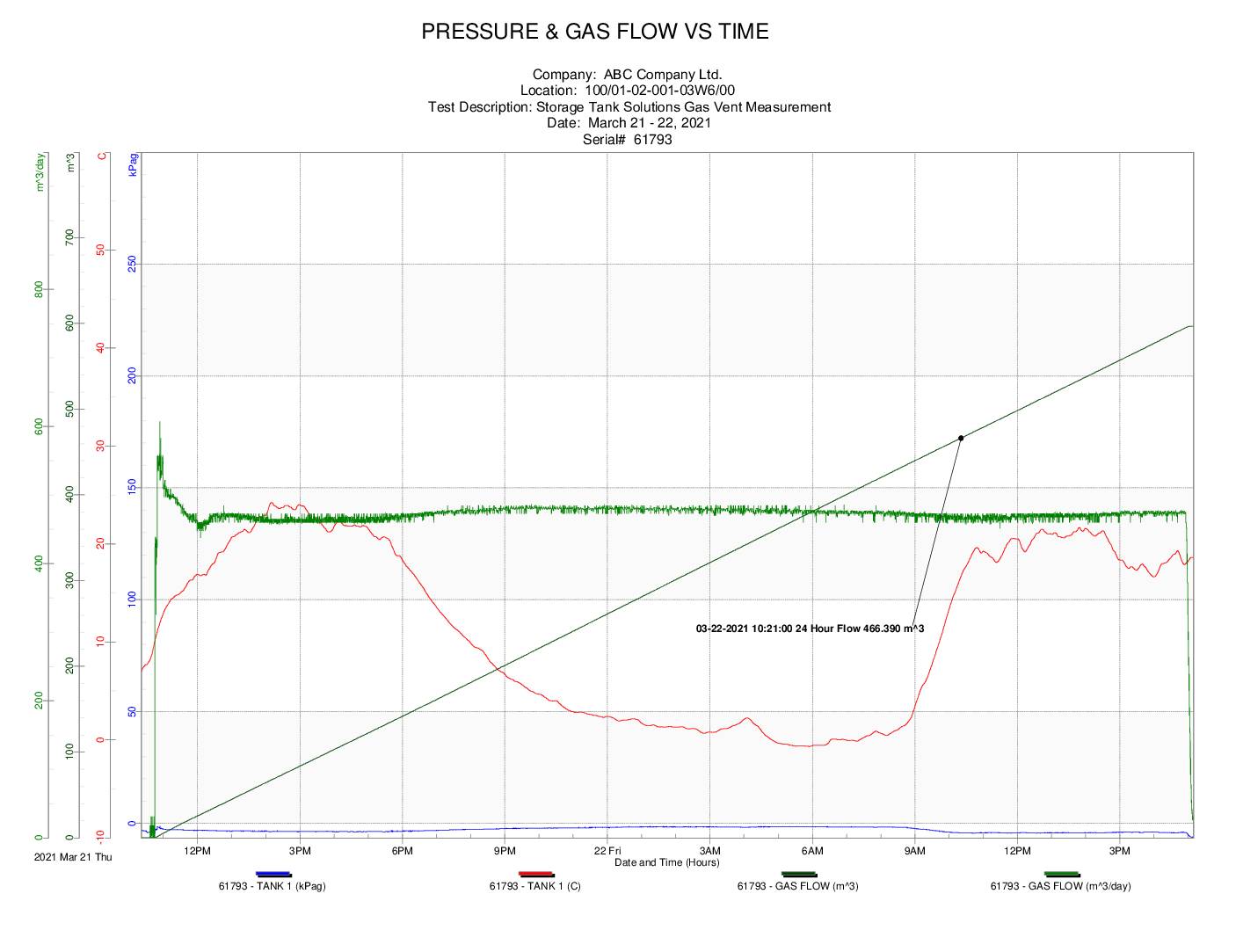

Storage Tank Vent Measurement

The industry’s goal is to have the upstream petroleum industry continue to reduce the volume of solution gas routinely flared, incinerated, and vented. Because of this, regulators expect upstream petroleum to pursue continuous improvement in reducing solution gas flaring, incineration, and venting. Please call us to see how SSI can help determine your vent gas limits on single well oil batteries.

Learn more about our Storage Tank Vent Measurement.

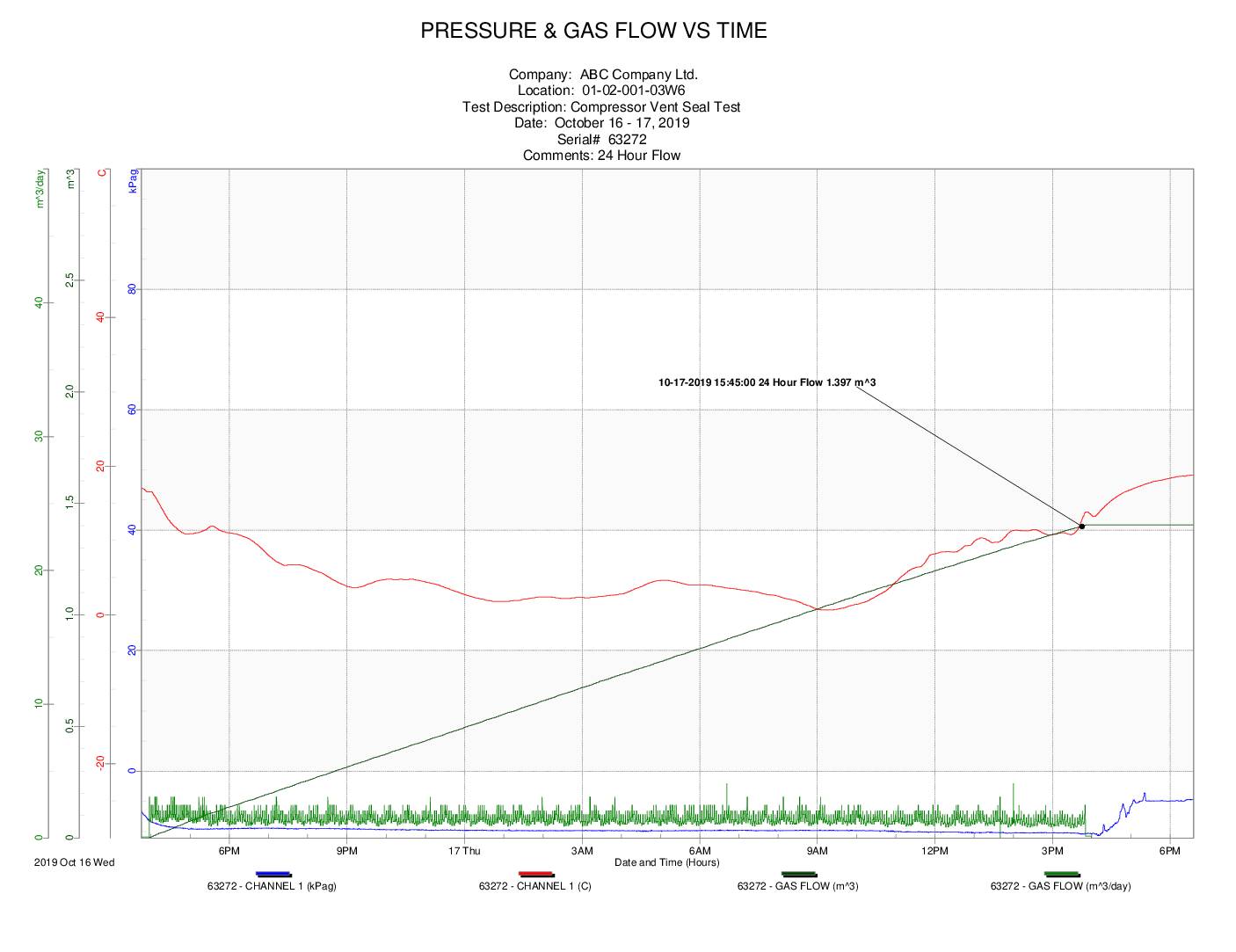

Compressor Seal Vent Testing

The vent gas limits in this section apply to vent gas from the seals of a reciprocating or centrifugal compressor that is:

- rated 75 kW or more; and

- is pressurized for at least 450 hours per calendar year.

SSI has the equipment and knowhow to quantify these emissions. Ask for more information on each report and how the easy-to-read format is accepted by the AER.

Find more information on our Compressor Seal Vent Testing.

Glycol Dehydrator Quantification

The duty holder must limit methane emissions from each glycol dehydrator installed or relocated on or after January 1, 2022, to less than 68 kg of methane per day. Vent gas from glycol regenerators used in the refrigeration processes is managed under the OVG limit and therefore is excluded from the January 1 limit. SSI can schedule testing and advise on a testing program.

Learn more about Glycol Dehydrator Quantification.

Fugitive Emissions Survey

SSI uses state-of-the-art gas imaging cameras that can detect a stream of pure methane gas emitted at a rate of 1.0 gram per hour or less. We ensure that it is operated within AER mandated protocol, with six metres of the equipment being surveyed. While conducting our surveys, SSI always surveys:

- Equipment components with hydrocarbon throughout;

- Hydrocarbon gas-driven pneumatic devices;

- Tank-top equipment, including their hatches and gauge-board assemblies;

- Surface casing vents and the area around the wellbore;

- Equipment used to destroy vent gas, including burners, flame igniters, pilots, and combustors; and

- Equipment used to conserve vent gas, including vapour recovery units and vent capture systems.

Find out more information if you are interested in our Fugitive Emissions Survey.