Storage Tank Vent Measurement

An ongoing initiative of the oil and gas industry regulators is to have the upstream petroleum industry reduce the total volume of solution gas that is flared or vented. Government agencies and stakeholders use data from active worksites to monitor progress and determine the need for additional requirements to facilitate solution gas conservation.

Surface Solutions works with operators to provide them with relevant data to help them determine their vent gas limits on single-well oil batteries. The recovery and redirection of gas identified by the data collected that would otherwise be vented or flared for other useful consumption can be used as fuel for production facilities, power generation, consumer sales, or in addition to an oil or gas pool.

Regulators expect conservation to be implemented at all oil and gas facilities. However, exclusion may be approved site-by-site on facilities where conservation is not practical or economical. If gas is not conserved at an oil facility, the flare is expected to be visible from a populated area. In that case, incineration should be considered during the facility application process.

Gathering the solution gas from several flares or vents at a common point, known as clustering, can also be used for conservation.

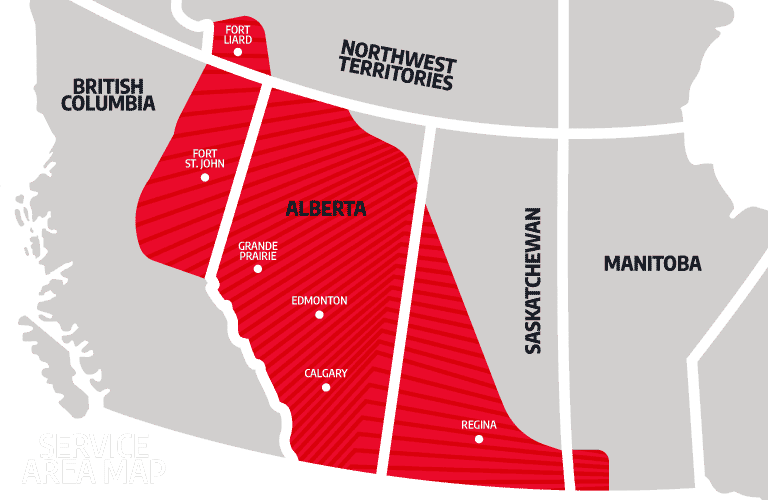

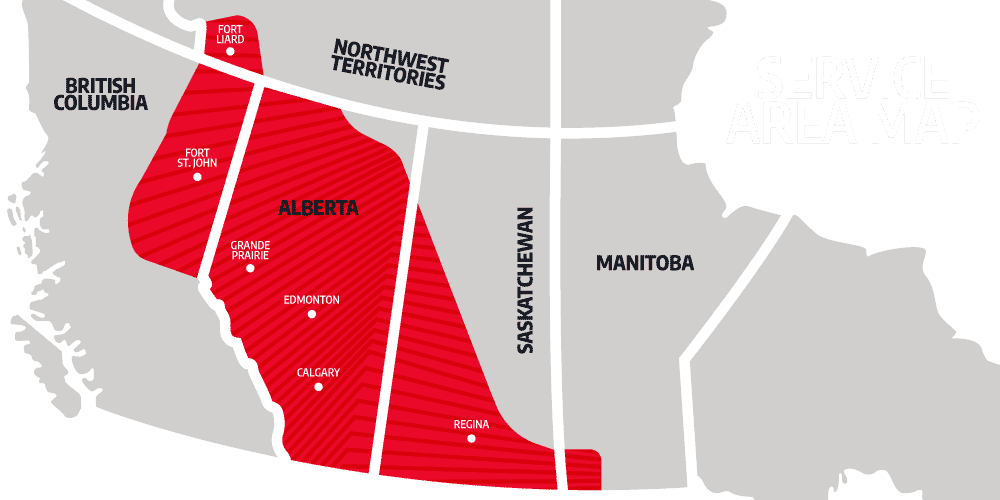

With the technological advances in real-time data acquisition, industry-leading oil and gas producers are now able to have test data that is flexible, affordable, and available in the cloud. Surface Solutions has built a solid foundation for our business based on our industry experience, safety leadership, and track record for excellent customer service.

Storage Tank Vent Measurement Emissions Testing

Surface Solutions’ storage tank vent measurement emissions testing services provide data that meets the rigorous requirements of the oil and gas regulators, including information highlighting the volume of gas produced to flare, vent, or pipeline and all analyses from samples gathered at the wellhead.

Gas used for pilot, purge, or blanket gas must be reported as flared or vented. Process gas used to operate instrumentation or as power gas to drive chemical pumps must be included as vented gas. Dilution gas is to be reported as fuel gas.

Surface Solutions testing procedures provide our customers with reliable data demonstrating that the volumes of gas are determined accurately and reliably. The analyzed data can inform the written documentation detailing the methodology used to determine incinerated, flared, and vented volumes for pipelines, wells, and facilities, needed by regulatory officials.

Vent Gas Management

For gas tied into an oil battery, or solution-gas tied into a gas facility, all incinerated, flared, or vented gas on a single production statement for the battery or facility must also be reported.

Oil and gas production processes vent a portion of the resulting natural gas. Vent gas management is an issue for most oil and gas operators. These vent and flare systems are heavily used in the oil and gas industry to dispose of waste hydrocarbon gases and vapors.

Intermittent venting and flaring are associated with various activities, including well emission testing and servicing, numerous depressurization events, compressor engine starts, maintenance and equipment inspection, pipeline tie-ins, pigging, sampling, and the removal of hydrates from pipelines.

Importance Of A Practical Management Strategy

Operators must balance permitting requirements, regulatory compliance, and corporate responsibility to minimize pollution, waste, and employee liabilities. Recovery of the vented gas grows revenue for the facility while releasing the gas into the atmosphere or combusting the gas results in air pollution. This makes an understanding of vent gas and a practical management strategy important. Data collected by Surface Solutions will inform these strategies.

Continuous applications most commonly occur at facilities where associated gas production above onsite energy needs is uneconomical to conserve because of the lack of economic access to a local market or dependable gas collecting system. There is generally an insufficient economic benefit to re-injecting the gas to maintain reservoir pressures.

The significant waste of valuable non-renewable energy resources and the harmful environmental impact of greenhouse gasses and other harmful emissions. Measuring flaring and venting has been identified as an important issue where regulators could significantly contribute to the global flaring reduction goals.

Flaring And Venting Natural Gas

At natural gas facilities, continuous flaring or venting may be associated with the disposal of waste streams and gaseous by-product streams that are uneconomical to conserve.

Until recently, the associated gas has often been assumed a by-product to be disposed of because of a lack of commercial options for its use or numerous safety considerations. As a result, producers and regulatory bodies elevated flare or venting measurement to a level comparable to the industry practice in measuring non-associated gas or oil.