Automated Acoustic Well Sounder

Automated acoustic well sounders periodically send, record, and interpret sound waves to determine an oil well reservoir’s characteristics. These devices operate by bouncing sound off the surface of the wellbore casing and well contents. The advantages of acoustic well sounders are their ease of use and instant, live data results. Compared to legacy testing procedures, acoustic well sounders do not require any measuring devices or physical structures to contaminate the well, and there are no probes or wires to hang out.

Detailed calculations of pressure buildup and drawdown tests are used to determine pump efficiency, reservoir pressure, productivity index, and skin factor. With this data, an operator can calculate the bottom-hole pressure of the wellbore to obtain a pumping well’s buildup and drawdown characteristics.

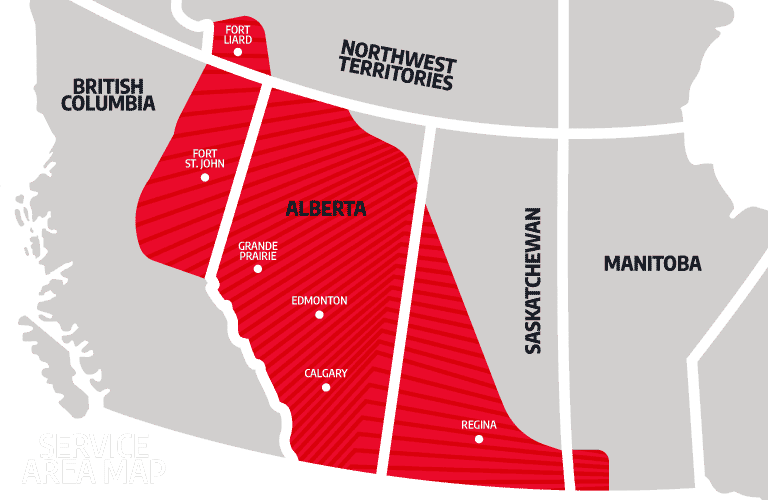

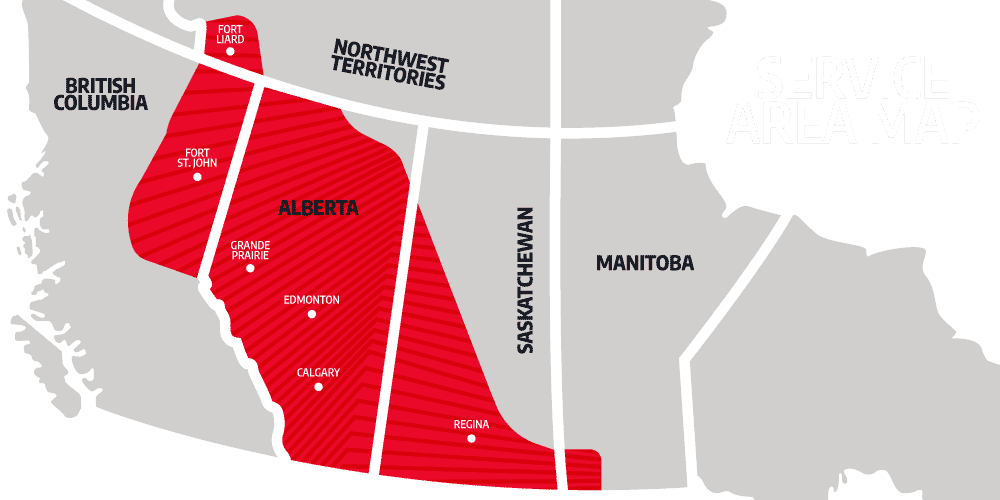

Per AER annual pool requirements, all companies must submit well testing in addition to gas and fluid analyses, absolute open flow, static and transient gauge pressure data, drill stem tests, and acoustic well-sounder data. Surface Solutions’ experts will walk you through electronically submitting your AAWS data to the AER and other Western Canadian regulators..

The Drawbacks Of Manual Acoustic Well Sounder

Designed as a simple-to-use self-contained acoustic ranging instrument designed specifically to find a pipe or borehole obstruction, which could be the surface of the liquid in the hole or the dry bottom. Internal non-volatile memory is enclosed to record system settings, calibration data, and logs up to 14,976 data points. A real-time clock/calendar is also included to time stamp the recorded log data.

The probe contains a speaker, a microphone, and a temperature sensor. The acoustic well sounder works by transmitting an acoustic pulse into the pipe, then measures the time the echo takes to return to the sensor. The distance is calculated using the sound speed and the time. Since the sound speed has significant temperature dependence, a temperature sensor is included in the probe to adjust for variations.

These simple gauges yield accurate data, but the overhead expense of gathering information on one well at a time. Each well requires the operator to initiate the acoustic pulse and interpret a data chart they record.

Obtaining many soundings over a longer period is necessary to define a buildup curve’s shape. Due to the operator time required to obtain each of these readings, the manually operated sounder rarely is used in this way.

Automated Acoustic Well Sounder

The automatic acoustic well sounder overcomes the difficulty of monitoring each well on its own by automatically measuring the liquid level during buildup and drawdown tests, often enough, and long enough to provide a detailed measure of the shape of the bottom-hole pressure curvature. The automatic acoustic well sounder uses the same acoustic well-sounding method as the manually operated devices.

This digital system prints out the actual depth to the liquid level in feet, the time of the audio, and the casing pressure. Measurements are all made automatically on a preselected schedule without an operator attending and sent to the cloud.

Calculating Bottom-Hole Pressure

In the natural gas industry, there is a recurring need to obtain accurate reservoir pressure data on gas wells. Accurate reservoir pressure is necessary to make good reserve determinations and analyze gas well performance.

Bottom-hole pressure can be measured directly with a bottomhole pressure instrument or calculated from a surface shut-in pressure. Economic considerations give added impetus to the calculation technique. Calculating bottom-hole pressures from surface pressures requires a correction for the presence of any liquids in the wellbore.

If liquids stand in the wellbore and are accounted for, the calculated bottom-hole pressure will be correct. Whenever the calculation technique for determining bottom-hole shut-in pressures is used, it is necessary to know the liquid level in the wellbore.

An acoustic well sounder is commonly used to measure the wellbore’s liquid level, which offers a reliable method of determining liquid levels under most wellbore conditions. However, wellbore conditions exist from which interpretable acoustic test data cannot be obtained. This article introduces and evaluates a concept for determining liquid levels in those wells from which a conventional acoustic well-sounding device cannot determine usable acoustic data.

Acoustic Well-Sounding Instruments

Acoustic sensing devices for locating anomalies in pipes have been used for over 50 years to locate lost mail cartridges in the pneumatic system that interconnected New York City’s postal stations. A quarter of a century later, a similar device was introduced to the oil and gas industry for locating the liquid in a pumping oil or gas well.

The acoustic method of determining the liquid level in a gas well starts with generating a sound wave at the wellhead and recording the echoes from the tubing collars and surface of the liquid. Reflecting sound waves are converted to electrical signals and recorded on a strip chart. The documented signals show the position of the liquid against a depth scale provided by the tubing collars.

To accurately determine the liquid level in a gas well with an acoustic well sounder requires a tally of the tubing in the hole and a well-defined tubing collar reflection record.