Pipeline Integrity Testing

Pipeline integrity testing refers to various processes and tests used to test a pipe’s structural integrity. Regulatory agencies across Western Canada mandate several preventative tests and documentation processes designed to standardize pipeline integrity measurement, testing, and assessment. Standardizing testing is key to mitigating costly pipeline failures and continues to be a top consideration for regulatory agencies, pipeline operators, and energy providers due to the hazard to human life and the environment. Staying up to date with the integrity and structure of pipelines is critical to planning and prioritizing preventative maintenance measures.

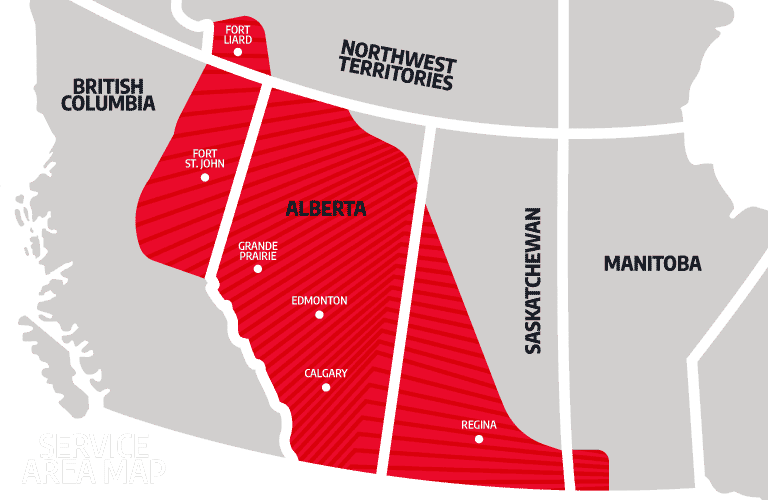

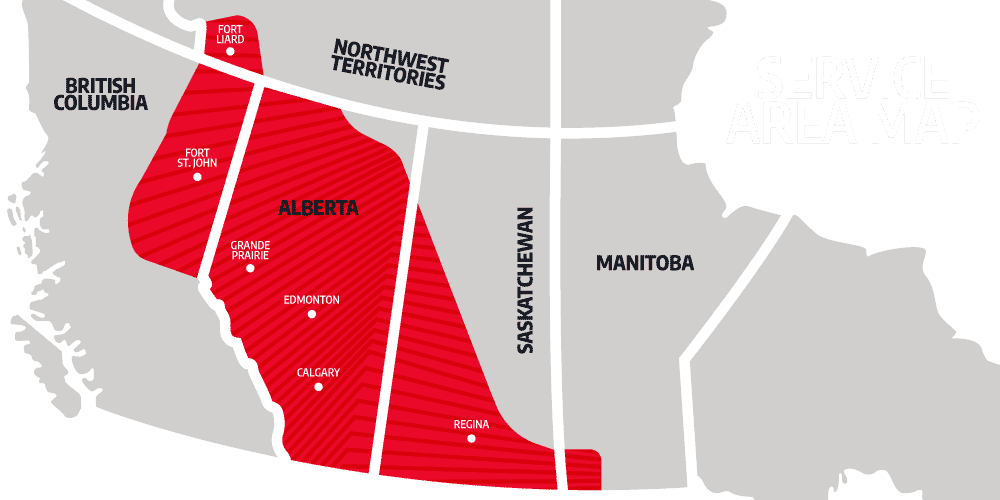

Surface Solutions has synergized our technical skill set, equipment, and test procedures with the Alberta Energy Regulator’s Directive 87, the British Columbia Oil and Gas Commission’s Operations Manual, and the Saskatchewan Ministry of Energy and Resources.

Pipeline integrity testing generally falls into two classifications, destructive testing (DT) and non-destructive testing (NDT). Non-destructive testing is used to evaluate a pipeline’s properties without destroying the original system’s serviceability. NDT addresses equipment performance, component reliability, environmental protection, and government regulations. Several different inspection methods are used in non-destructive testing to achieve complete safety in operations—without causing interruptions or shutdowns.

While the oil and gas industry uses destructive testing of the pipeline’s integrity is needed to reveal more in-depth structural analysis than non-destructive testing can provide.

Maintaining this integrity requires ongoing, destructive, and non-destructive testing of materials, welds, and components. Without the information this extensive testing provides, the potential for dramatic and costly pipeline failures will continue to be a top concern for regulatory agencies, pipeline operators, and energy providers in the oil and gas industry.

Surface Solutions works with our operators across Western Canada to fulfill each aspect of their region’s regulatory requirements for Pipeline integrity testing. Surface Solutions’ regulatory testing services utilize our industry-leading technological advances in data acquisition to provide oil and gas customers with precise, flexible, and inexpensive data.

Our technical skills and knowledge base, along with our equipment, gives us highly sought-after services recognized by oil and gas leaders in Western Canada who trust us to do the job and to do the job well.

Hydrostatic Testing

A hydrostatic test is one of the main integrity tests done on new pipeline systems and systems about to go online to determine whether a pipeline can safely hold the amount of pressure it is rated for. Hydrostatic testing also identifies leaks in a pipeline.

Hydrostatic tests ensure that the weld joints and flanges are fitted suitably while confirming that the material used has the critical strength to maintain the pressure. This is specifically important in industrial applications concerning the storage and transport of fuel, chemicals, and other unstable materials that can explode if they fail beneath pressure and in pipelines, where a deficiency in a pipe’s structural integrity could dramatically impact the environment and our economy.

High-flow “squeeze” pumps fill the pipeline with fluids bringing the pipeline’s pressure to the appropriate pressure level for testing. Any indication of a leak is flagged and repaired. The pipeline is then pressurized again, and the test is repeated. The functional integrity at the welds and joints, the hydrostatic tests in the field, and, even more important, the pipeline’s integrity is confirmed once the pressure test is completed successfully on a pipeline.

The pressure is then held for a specific amount of time to inspect the system for leaks visually. Visual inspection can be enhanced by spreading tracer or fluorescent dyes to the liquid to determine where cracks and leaks originate. Hydrostatic testing is widely used to reassess the integrity of hazardous liquids and transportation pipelines periodically. Once testing is complete, the pipeline is depressurized with an emphasis on health and safety, prevention of accidents, loss or damage of equipment, and personal injury to our employees, clients, the general public, or the environment.

Data is documented in our industry-leading cloud reporting system and made available to the operator remotely. Surface Solutions’ clients can view their test data in real-time when critical ambient temperature fluctuations make approvals tricky. This system puts data in the hands of stakeholders who must make decisions vital to keeping their business competitive in today’s market.