Offset Frac Monitoring

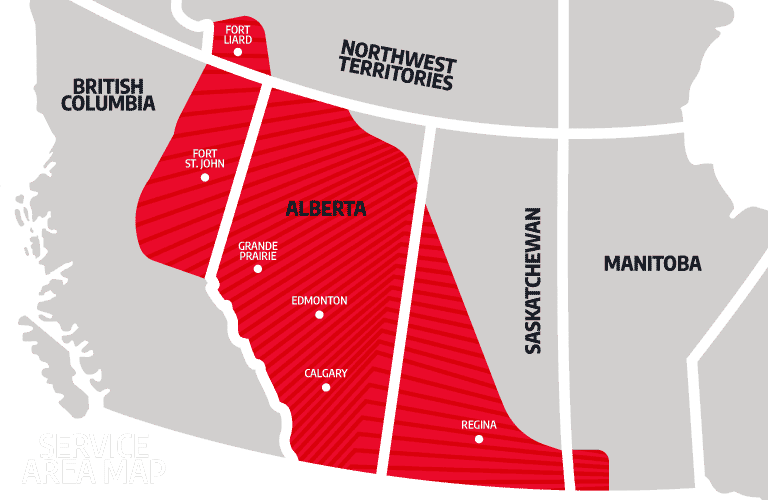

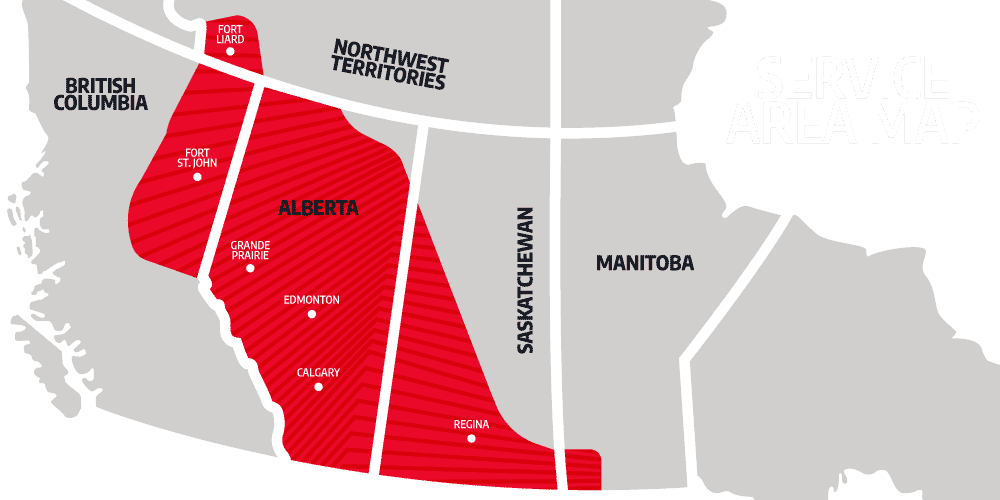

Surface Solutions are the industry leader in helping operators comply with Alberta Energy Regulator’s Directives, the British Columbia Oil and Gas Commission’s Operations Manual, and the Saskatchewan Ministry of Energy and Resources.

AER directive 83 sets out the requirements for managing subsurface integrity associated with hydraulic fracturing subsurface operations, including requirements to prevent loss of wellbore integrity, manage well control at an offset well, and prevent surface impacts and impacts to non-saline aquifers and water wells.

Surface Solutions created the industry’s first web-based multiwell pressure data, allowing test data to be viewed through the internet as it is acquired in the field. Traditionally waiting for data from the field to populate in an easily analyzable way meant that stakeholders were waiting on and working from outdated data. Updated data directly from the field means stakeholders make real-time decisions.

Our industry-leading inter-well communication systems provide our customers with high-value data points that can be brought into 3rd-party systems or used in Surface Solutions reporting.

We continue leading industry reporting in Western Canada through new technologies and utilize an extensive cloud-based data system to store our customer’s entire testing history. Past data is continually analyzed to review and refine our testing methodologies and help us provide more accurate frac mapping in the future.

What is Hydraulic Fracking

Hydraulic fracturing or “fracking” is a technique used to create pathways in rocks deep underground to help get natural gas flowing.

Natural gas needs help to flow through rock, into a well, and then to the surface. To create pathways through the rock, fractures are created and kept open by pumping sand, water, and several chemical additives down a well bore. This is done at a high enough pressure to fracture the rock and drive the sand mixture into the fractures. When the pumping stops, the sand helps keep these pathways open.

Offset Frac Monitoring Uses

Frac Planning maps can be used to assist in surface casing vent flow tests (SCVF), and gas migration (GM) tests on the subject well, on wells in the fracture planning zone (FPZ), and on other offset wells that are considered at-risk for inter-wellbore communication. Proper planning can allow neighboring producers to be up to date with their assets alongside the fracturing operation. Accurate pressure alarms will notify the end user of any unintended wellbore communication and allow operators to shut in wells to avoid spills or other high pressure events.

An SCVF test, also called a “Bubble Test,” is used in regions where wells are operated with a surface casing vent in the open position. Fluid or gas entering the annulus can escape through the surface casing vent resulting in a surface casing vent flow (SCVF). Real-time surface casing vent flow (SCVF) equipment can be installed on the subject well to identify internal gas migration to the surface. Surface Solutions’ industry-leading report format can be submitted directly to the DDS portal or eSubmissions.

Surface Solutions can pinpoint the source of the gas migration and the concentration of biogenic or thermogenic methane. Extensive experience with risk assessments, carbon isotope analysis, and groundwater protection surveys make our reports critical to proper wellbore remediation. When no wellhead is present (cut and capped) Surface Solutions is still able to report if a communication event occurs. Call us for more detailed report information.

One of the more recent developments that creates value for the client is understanding your fracture driven interactions (FDI). Accurate, high resolution data is a key reason why clients prefer Surface Solutions. Poroelastic events also known as frac shadows, or frac hits may have negative impacts on a neighboring well production. Unintended wellbore communication can be studied long after events are reported and can have lasting effects on production forecasts. Call Surface Solutions today to learn more about how parent/child well communication can help engineers with their production impairment analysis.