Fluid Level Determination

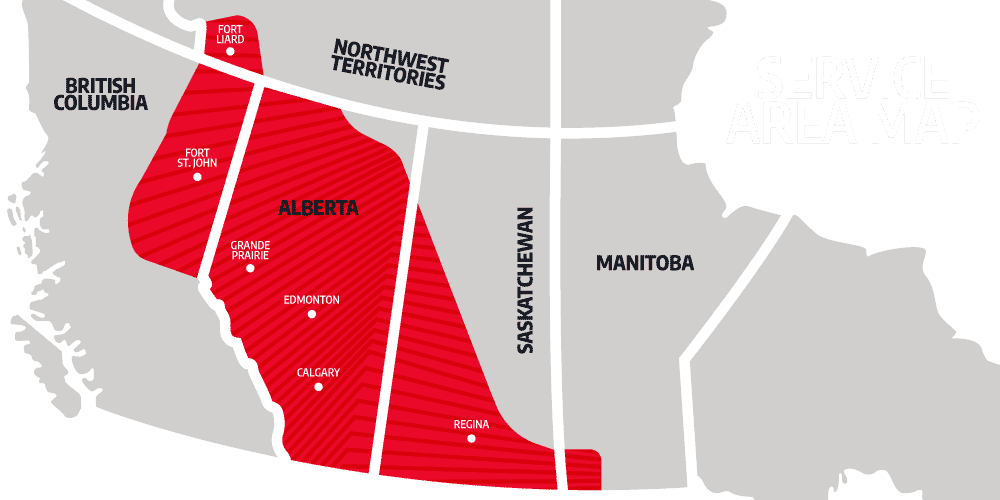

As the industry leader for over 20 years, Surface Solutions works with our clients to identify optimization opportunities in various artificial lift situations.

With the advent of portable digital controllers, Surface Solutions we save our client’s records over time in a cloud database to allow our clients the ability to visualize their optimization effectiveness.

Through the automatic firing of an acoustic pulse and recording of the time to the liquid level echo and calculation of its depth, our fluid level determination tests do not require an operator to be present. With the ability to record the depth of the liquid while the apparatus is unattended, obtaining the build-up characteristics of a marginally producing well would only be able to be measured over a short period. The casing pressure is also recorded to determine bottomhole pressure in a producing well.

Surface Solutions’ experts analyze the records registered on a digital chart during the fluid level determination, verify the results, and package them in a way that can be submitted to regulatory agencies. By automating the fluid level determination tests, human error is substantially eliminated, and adjusted calculations for changing downhole conditions are more effective.

Processing recorded reflections utilizing known values, the average pressure pulse velocity of the gas in the well can be determined and used with the pulse travel time of the liquid surface reflection to calculate its actual location in the well. This technology makes it possible to accurately determine the fluid level’s depth in most wells, even in background noise caused by gaseous, liquid columns.

Fluid level determination testing provides instantaneous information regarding the progress of the pressure transient test allowing the operator to make business decisions that ensure the test will yield accurate and consistently complete and accurate data. A preliminary analysis of the data completed at the well site can be followed up with a detailed transient analysis by exporting the data to the office.

Technological Advancement With Fluid Level Determination

The importance of technological development and the need for continued advances within the oil and gas industry only increases yearly as resources become more limited and the competition between operators increases.

Fluid level determination measurement can assist in the productivity of well operations and the well flow rate capacity identification. By doing this, operators can identify faulty flow valve positions for gas-lift operations and optimize the speed, size, and location of submersible pumps for fluid extraction.

Surface Solutions’ advanced equipment and software can diagnose wellbore anomalies that could be holes in tubing or even wax build-up. Our state-of-the-art equipment and software have revolutionized a historically expensive and operationally time-consuming process and our constant commitment to invest in the training our staff on the latest technologies exemplifies our dedication to providing our customers with the best.

For these reasons, this acoustic method has continuously evolved and generally requires advanced signal processing procedures for reliable data interpretation.

Artificial Lift Methods

Artificial lift methods, or ALMs, are used to lift the collected fluids from wells and to help sustain their overall performances. As a way of producing gas using liquid-level detection in oil or gas, these artificial lift systems include sub-surface gas lifts, beam pumps, progressive cavity pumps, and submersible pumps.

Artificial lift systems allow operators to plan a response to a known liquid level inside the wellbore. Knowing these levels allows operators to prevent the well from pumping off and damaging the artificial lift system. Additionally, artificial lift systems reduce the chances of the liquid level in the wellbore dropping to an unnecessarily low level.

The fluid level detection method should always include detecting the pressure in the wellbore to determine the level of liquid in the wellbore for the automated control of any liquid removal.

Another artificial lift systems method calculates the pumping from the well in conjunction with automated fluid level control to maximize fluid level in the wellbore without interfering with production. A timing method allows for control of the quantity of gas injected during the injection cycle of a subsurface gas lift artificial lift system. Surface Solutions uses only the best diagnostic tools to detail all downhole anomalies to eliminate detection errors.

In short, level sensors are very important and play a very important role in various consumer/ industrial applications. The selection of an appropriate type of sensor that matches the application requirement is very important. With over 20 years tracking well acoustics Surface Solutions realizes it’s not always as simple as finding the top of fluid level that our clients seek answers to.