Pipeline Optimization

Oil and gas pipelines transport millions of dollars of products daily, and optimizing their long-term strategies is an essential target for all operators. Improving the economic benefits of a pipeline’s operation and reducing the system’s energy consumption by optimizing the pipeline’s operation scheduling scheme is a practical undertaking for any oil and gas operators struggling to define an effective solution to solve their slugging challenges.

Surface Solutions provides operators with high accuracy and high-resolution surface data that provides a clear picture of what exactly is happening in their pipeline gathering system and when it’s happening.

As a result of the current market approach, operators tend to be more reactive to issues, and rather than work with experts to create an optimization plan instead, they implement processes developed by train and error, which ultimately ends in unsatisfactory solutions.

Operators face a constant business imperative of managing the complexity of their operations while further enhancing their business performance. Operators seek to optimize operational costs, improve pipeline capacity utilization and mitigate business risks by undertaking transformative optimization programs. This can often create bottlenecks that restrict a producer’s ability to gain market access.

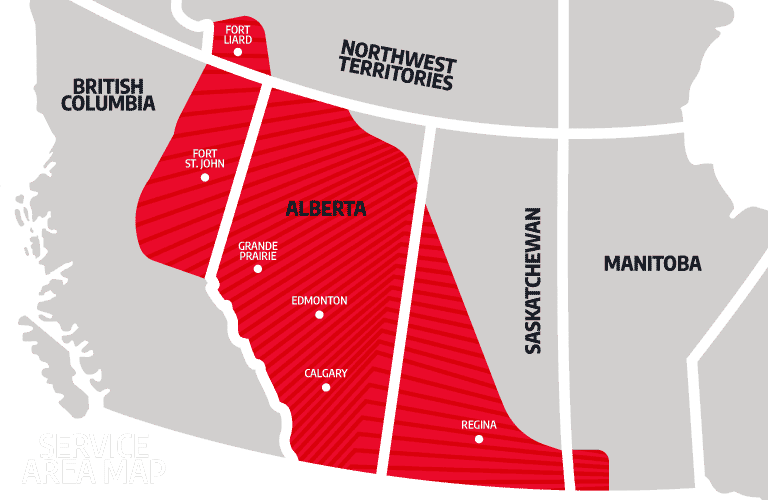

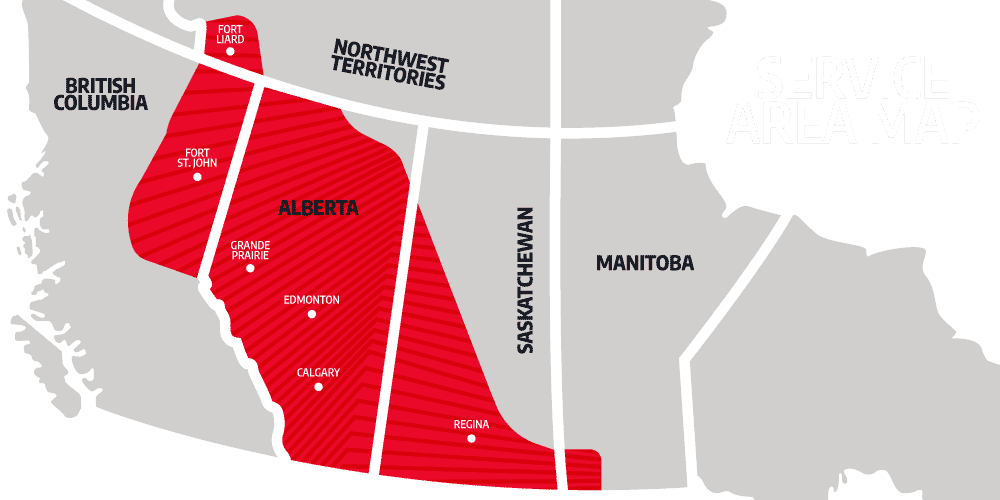

Surface Solutions’ experts work with Western Canadian operators to optimize pipelines across multiple variables, including pipe diameter, pressure, temperature, line length, required inlet, delivery pressures, and quantity. Optimizing pipelines also involves business decisions, such as the number versus the size of pipelines, the utilization of satellite stations, and the position of pumping or compressor stations along the route.

Environmental concerns also create notable challenges for the oil and gas industry. Pipeline operators are working to find a way to meet environmental codes and regulations while continuing to optimize their systems and run efficient cost-effective systems.

Contact Surface Solutions to learn more about how with effective implementation, our pipeline optimization testing will cut your operational costs.

Optimizing Natural Gas Pipelines

The most convenient, economical, and reliable method of transporting natural gas(NG) cross-country is via pipeline transport. The increasing industrial and commercial importance of natural gas due to its inherent properties have resulted in the need to optimize its movement through pipeline systems.

These pipeline systems are often referred to as highways of natural gas transmissions. Natural gas is transported at high pressure, reducing the overall volume of natural gas transported and providing a propellant force to move the natural gas through the pipeline.

Gathering natural gas usually involves connecting wells in different oil and gas fields that can be spread across vast geographical and topographical areas. Supplying gas and its associated liquids to end users often requires an extensive network of compressor stations, pipelines, degassing stations, and processing plants. As well as storage facilities and shipping terminals for the liquids. These cross-country networks offer operators multiple options for optimization.

Natural gas resources are gaining increasing importance as an energy source to fuel the world’s economic growth in both emerging and established economies. Pipelines play a notable role in evolving and producing gas reserves as they provide one of the most reliable means of transport. The growing need to supply transportation infrastructure between major gas-producing regions, countries that want to import gas, and future oil transmission systems.

Optimizing a natural gas pipeline involves several variables, including line length, space between compressor stations, required inlet and delivery pressures, pipe diameter, temperature, and quantity. Each parameter influences the general construction and operating cost and can be implemented during initial development or when upgrading an existing system. The biggest difference being the extent to which some variables are already fixed.

Optimizing For Cost And Safety

Establishing an optimum plan requires investigating several options when designing a pipeline optimization plan. Surface Solutions’ investigates all possible scenarios to ensure that no possibilities are overlooked and that all future unknowns can be adequately covered. Our expert processes have been developed to provide industry-leading solutions to optimize the pipeline system’s design and allow for the rapid analysis of the effects of consequential variables on the optimum design.

The growth of the natural gas network has allowed operators to move toward more throughput while pushing for better dependability of the pipeline network to fulfill transportation requirements.

Previously, optimizing natural gas pipeline networks has been mainly focused on reducing operating costs, with little concern about the reliability of pipeline networks. Surface Solutions’ emphasizes both our operator’s profits, as well as safety.

Surface Solutions’ production optimization services utilize our industry-leading technological advances in data acquisition to provide our oil and gas customers with test data that is accurate, flexible, and affordable. Surface Solutions’ business foundations are based on our experienced leadership and recognized customer service.

By utilizing our industry-leading database, Surface Solutions saves our customers time and money while managing their complete production foam depression testing needs.