Compressor Seal Vent Testing

In the oil and gas industry, reciprocating and centrifugal compressors move natural gas containing methane through pipelines. These compressors, even when maintained, have seals that wear and start to vent some of this natural gas as part of their normal function.

As methane gas is 25-28 times more potent as a greenhouse gas than CO2, most regulators suggest burning methane as an acceptable way to deal with vented natural gas currently, reducing your impact on greenhouse gasses. From an environmental perspective, maintaining the compressor’s seals to conserve the gas is still better than combusting it as it eliminates a source of emissions.

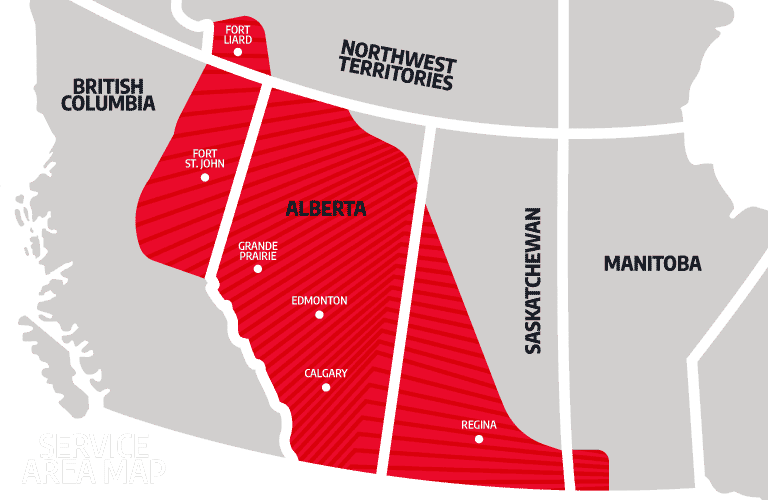

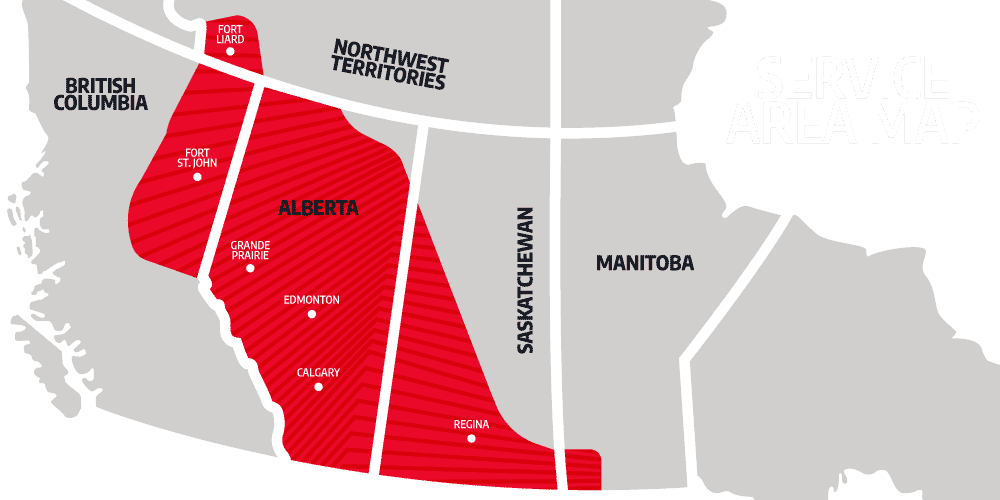

Annually in Canada from 2020, all compressor vents and their seals must be measured to ensure that no excessive vent flow rates are contributing to greenhouse gas emissions. Surface Solutions has the know-how and equipment to quantify these emissions through compressor seal vent testing to guide our customers in choosing the most cost-effective solution for their instance or facility.

Our team of experts can walk you through the required reports and the report formats the AER and other Western Canadian regulators accept.

Increased Pressure Needed for Unconventional Formations

Oil and gas production from irregular formations like fine-grained shale deposits or shale plays has grown rapidly over the last 3 decades and will continue to grow steadily. Led by the sustained development of tight gas, shale gas, and coalbed methane resources, and the innovations in techniques like horizontal drilling and hydraulic fracturing continue to drive growth.

Lower gas leakage and, as a result, lower emissions have been seen with dry seals, as well as lower operation and maintenance costs compared to wet seal compressors. They are mechanically simpler, require less power to operate while being more reliable, and require significantly less maintenance, making them the more common choice for oil and gas production from unconventional formations.

Emissions from Compressors

Compressors are the largest source of emissions at multiple stages of oil and gas production, from initial gathering and boosting, processing, general transmissions, and storage. Even when in good standing order, these emissions increase over time as compressor components begin to break down. Leak emissions from various compressor components can contribute to the issue, but vented emissions are the most common.

Compressors are used to increase the natural gas pressure to transport natural gas from the production site via the supply chain to the end consumer. Generally, vented emissions from these compressors occur from wet seal compressors or the packing surrounding the mechanical compression components of reciprocating compressors.

Compressors in the Oil and Gas Industry

Compressors play a role in all aspects of natural gas development. In production, compressors are used at the wellhead to compress the gas to remove fluids or equalize pressure with gathering equipment systems.

Reciprocating and centrifugal compressors are both used in the oil and natural gas sectors. A reciprocating compressor will increase the pressure of processed gas by positive displacement, utilizing linear movement of the driveshaft. In comparison, a centrifugal compressor increases the pressure by drawing in low-pressure natural gas and pushing out significantly higher-pressure natural gas employing mechanical rotating vanes or impellers.

Reciprocating Compressor

In a reciprocating compressor, natural gas enters a suction manifold. It flows into a compression cylinder, compressed by a reciprocating piston by a crankshaft powered by an internal combustion engine.

A key component of the reciprocating compressor is the reciprocating compressor rod packing. In machined metal cups, flexible rings fit around the reciprocating compressor piston rod allowing the rod packing system to create a seal, reducing the amount of compressed natural gas escaping into the atmosphere.

Over the compressor’s operating life, the rings and packing system will wear, resulting in higher leak rates. Emissions from the packing systems can come from four main components; the nose gasket, around the rings, between the rings and the shaft, or between the packing cups themselves.

Mitigating emissions from reciprocating compressors generally involve techniques that will limit the leaking of natural gas. This can look like replacing the compressor rod packing, replacing the rod itself, or refitting and realigning the piston rod.

Centrifugal Compressors

In centrifugal compressors, a rotating disk or impeller increases the overall velocity of the gas as it moves through a duct section that will convert that velocity energy to pressure energy. Primarily used for continuous or stationary natural gas transport, these compressors are mostly used in the transmission and distribution pipelines.

Centrifugal compressors can be equipped with a dry or wet seal. A wet seal collects oil around the rotating shaft of the compressor, essentially blocking the compressed natural gas from escaping. A dry seal operates mechanically under the force created by hydrodynamic grooves and static pressure.

Both seals enable the emissions to be captured and diverted to a combustion device or another environmentally beneficial process. The emission mitigation options for centrifugal compressors first work to limit the leaking of natural gas along the rotating shaft by using a mechanical dry seal or capturing the gas and routing it to a good process or a combustion device.

Dry and Wet Seal Compressors

A wet seal uses oil pooled around the compressor’s shaft to prevent natural gas from escaping when the shaft exits the compressor’s casing. This oil is then circulated at high pressure forming a barrier preventing any natural gas leakage and absorbing some of the compressed natural gas that may be released into the atmosphere.

A dry seal compressor uses the force created by the grooves and springs to provide a complete seal. When not rotating, springs force the compressor’s stationary ring against the rotating ring. When the compressor shaft rotates at high speeds, there is only one pathway for the gas to leak through, between the rotating and stationary rings, pumping the gas between the rings by grooves in the rotating ring.

The rings do not wear or need lubrication because they are not in contact with each other. Combining two or more dry seals in a series is called “tandem dry seals” and effectively reduces gas leakage.

Gas emissions from wet seal centrifugal compressors are higher than dry seal compressors primarily due to the off-gassing of the entrained gas from the oil. This gas is not suitable for sale and is either released into the atmosphere, flared, or routed back to a process.