Regulatory

Compliance

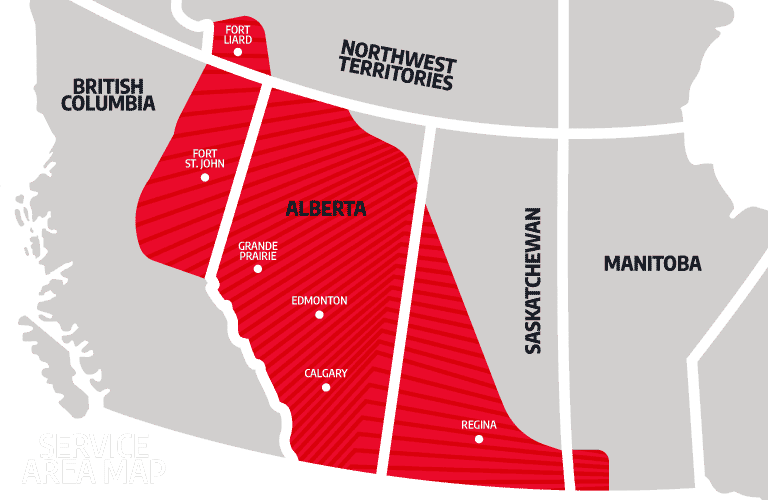

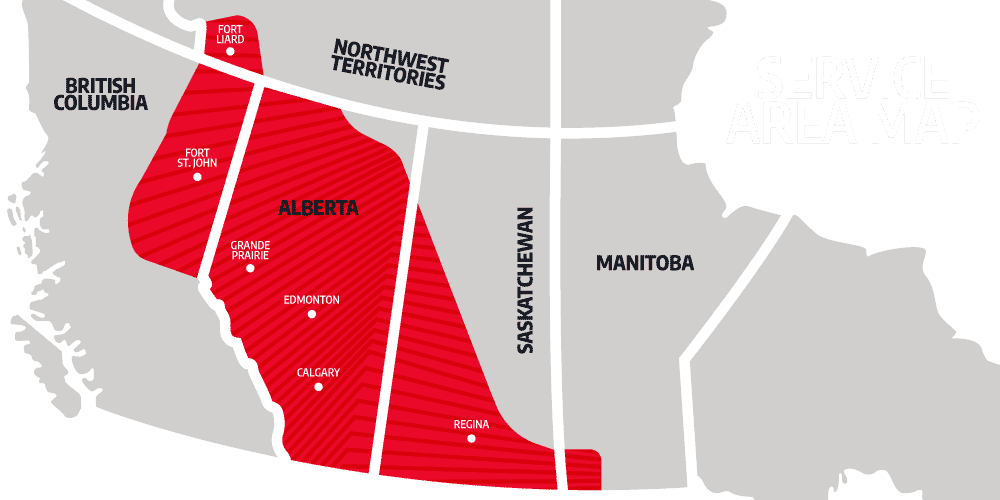

Surface Solutions has synergized our technical skill set, equipment, and test procedures to the Alberta Energy Regulator's Directive 87, BC Oil and Gas Commission's Operations Manual, and the Saskatchewan Ministry of Energy and Resources.

With technological advances in data acquisition, oil and gas producers are able to have test data that is flexible and affordable SSI has built a solid foundation for business, based on leadership and excellent customer service.

Planning is key at SSI – by utilizing our database, we save you time and money while managing your complete regulatory needs.

Gas Migration Testing

Both active and suspended wells may have external gas migration towards the surface. SSI can pinpoint the source of the gas migration as well as the concentration of biogenic or thermogenic methane. Extensive experience with risk assessments, carbon isotope analysis, and groundwater protection surveys make SSI reports critical to proper wellbore remediation.

Read more about our Gas Migration Testing.

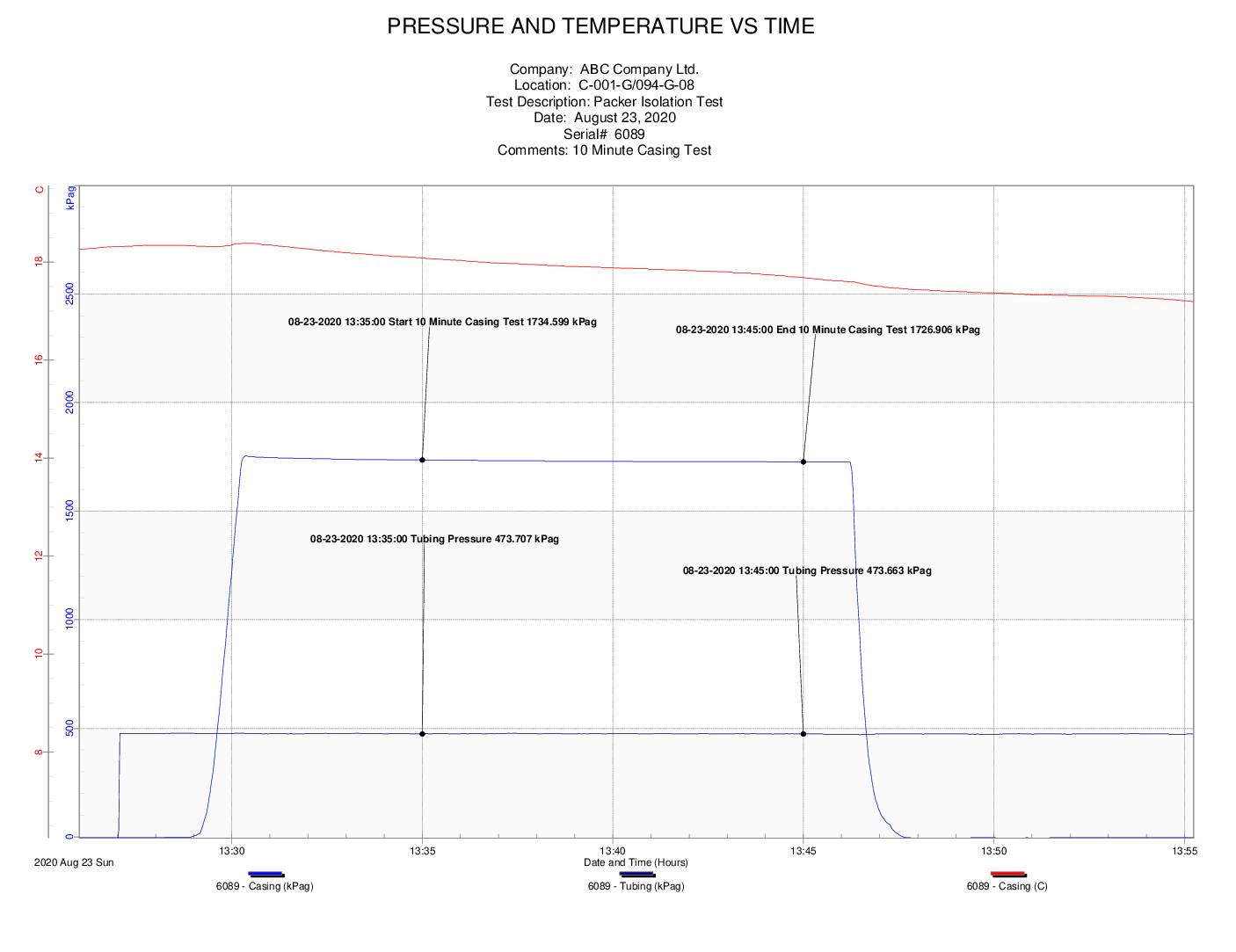

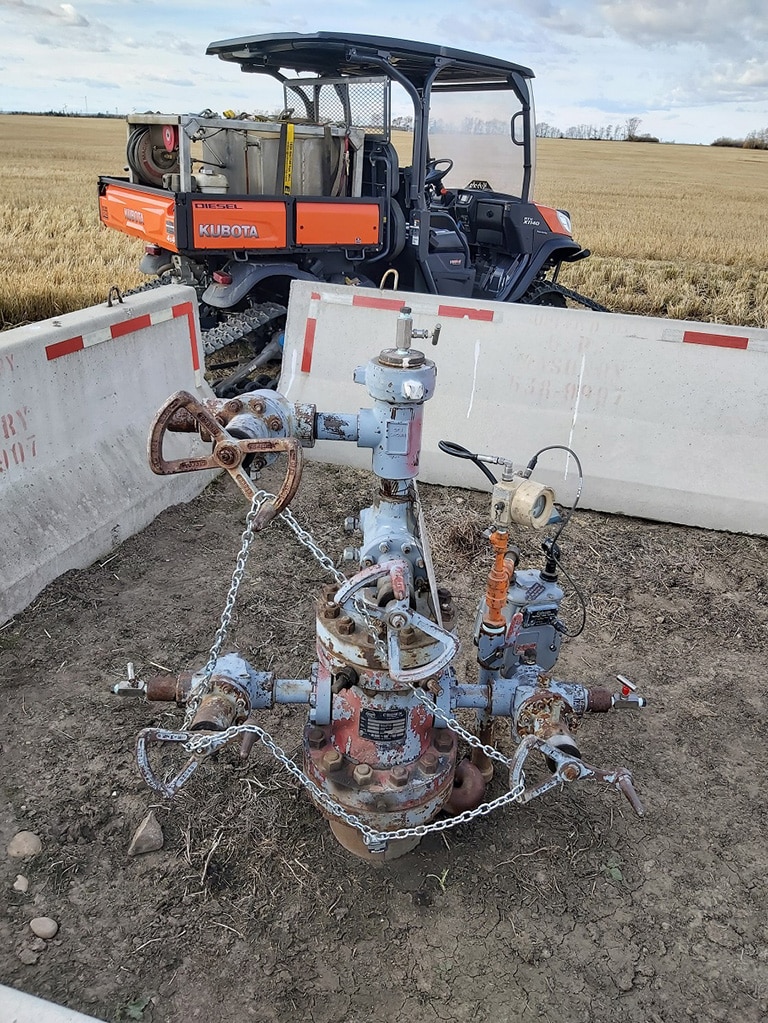

Packer Isolation Test

SSI completes our PIT using a dual-channel, temperature-compensated pressure recorder. This is key to confirm segregation between wellhead barriers as well as annular integrity. Our unique reports offer casing integrity, wellhead seal, and packer integrity to pinpoint where an issue may be taking place. We have an extensive test history that complies with SMER, AER, and OGC requirements.

Learn more about our Packer Isolation Testing.

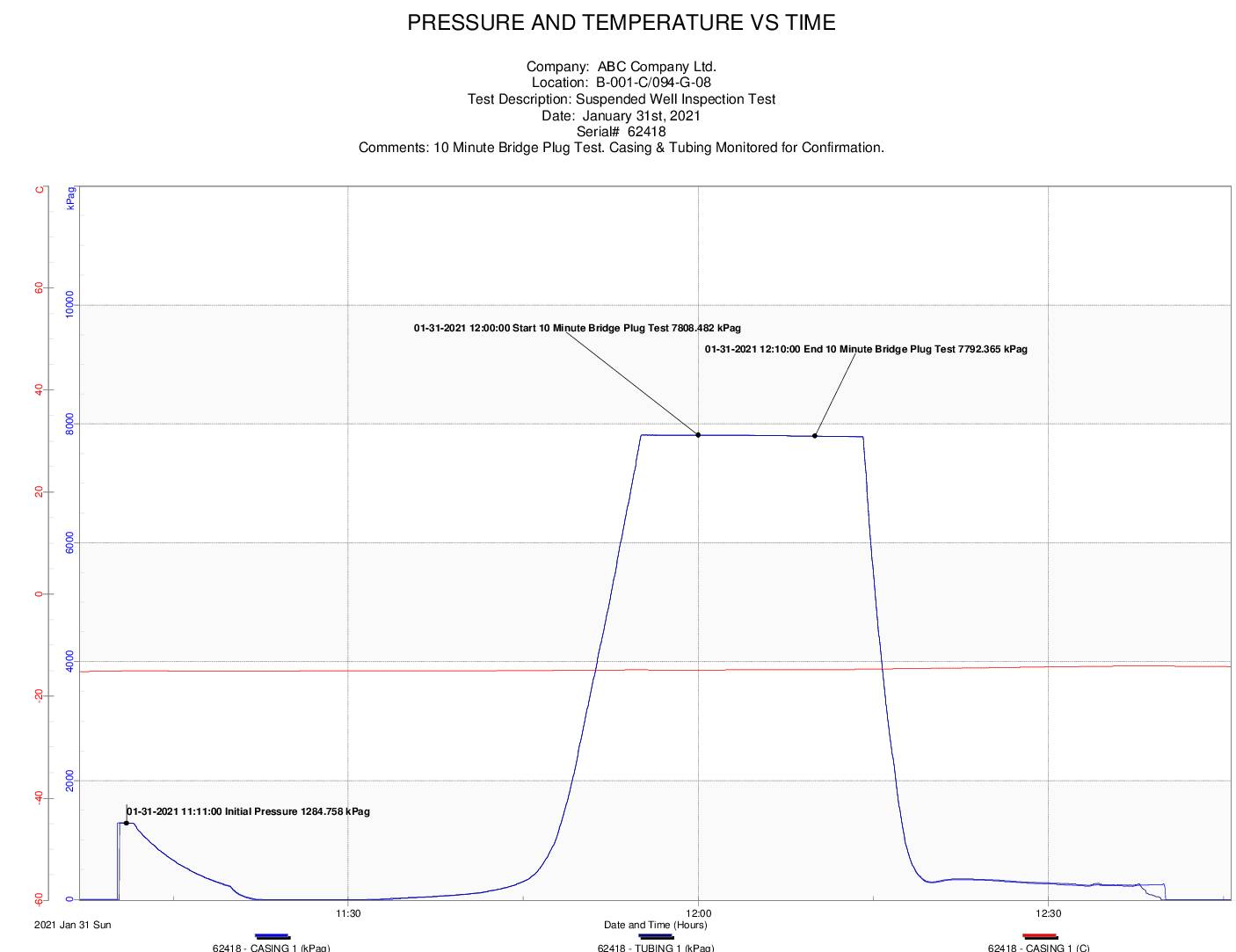

Suspended Well Inspection

Verifying the integrity of suspended assets takes attention to detail. SSI completes all aspects of the regulatory requirements including surface casing vent flow indication and gas migration, as well as any pressure tests that are needed to ensure environmental diligence. Our logistics, planning, and turnkey reports help cut costs.

Discover more information about our Suspended Well Inspection service.

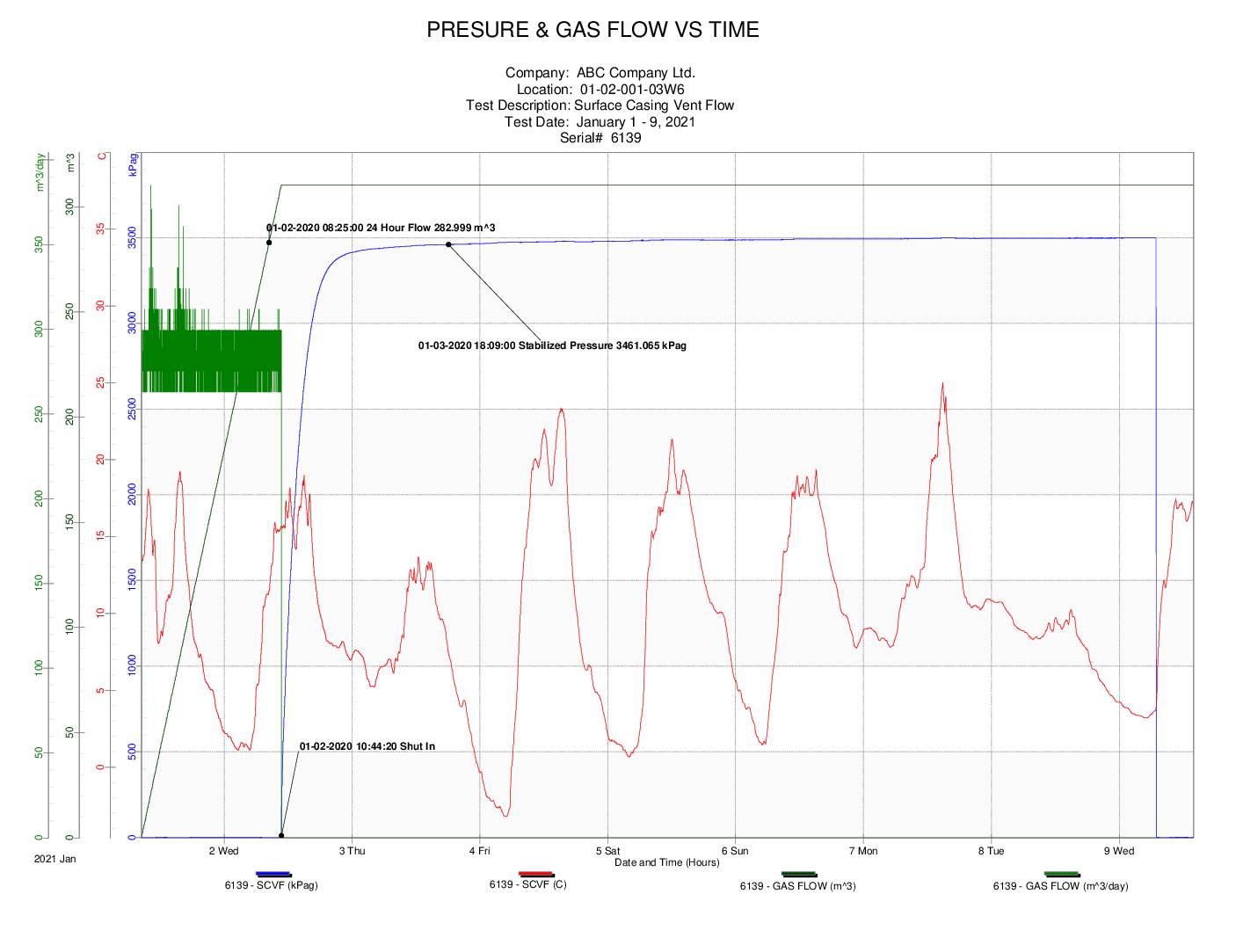

Surface Casing Vent Flow Test

Emissions requirements have seen technical growth in how SCVF is reported. SSI is a leader in digitized gas flow that can be audited by the AER. Our in-house water analysis helps cut down both on turnaround time and lab costs associated with liquid SCVF. SSI has a well-known track record for offering carbon isotope sampling that gives proper results, allowing for key decisions to be made when it comes time to abandon a well. All of this experience is logged in our industry-leading report format and can be submitted to the DDS portal or eSubmissions.

Continue reading about our Surface Casing Vent Flow Test.

Pipeline Integrity Testing

Hydrostatic pipeline testing is a carefully planned and controlled process that gives producers an opportunity to confirm a threshold measurement for safe operations, according to regulatory standards. A hydrostatic test is performed following all new pipeline construction, prior to placing a pipeline into service. SSI testing procedures confirm pipeline integrity and shipping capacity. SSI can allow clients to view their test in real time when critical ambient temperature fluctuations make approvals tricky.

Continue to learn more about our Pipeline Integrity Testing.