Production

Optimization

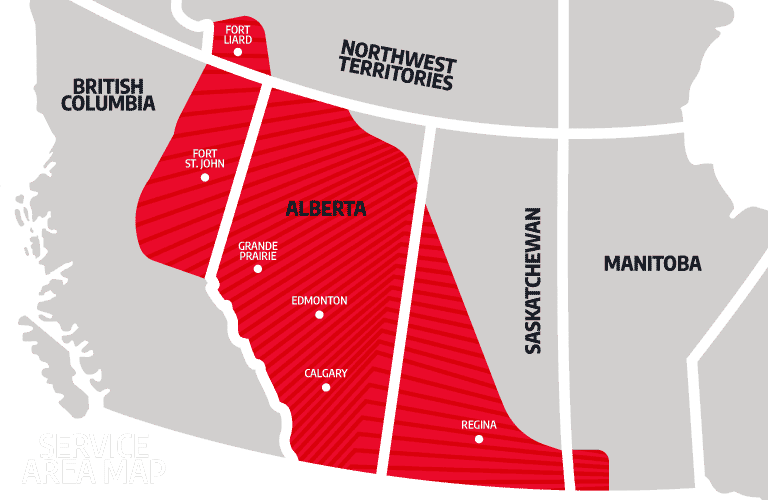

Founded in 1999, Surface Solutions Inc. has remained focused on complete and accurate oil and gas well optimization.

With technological advances in data acquisition, oil and gas producers are able to have test data that is flexible and affordable. SSI has built a solid foundation for business, based on leadership and excellent customer service.

Planning is key at SSI – by utilizing our database, we save you time and money while managing your complete production testing needs.

Dynamometer Test

“Dyno” evaluations are conducted on a pumping unit for diagnostic reasons. Load and position of the polish rod are accurately measured by our factory-trained technicians during operation. Data is gathered, then analyzed to decide if the pumping unit is optimized. Our fieldwork is conducted with commitment to safety and efficiency. Dynamometer testing should only be completed by trained professionals.

Discover more about our Dynanometer Test services.

Automated Acoustic Well Sounder

An acoustic survey monitors the pressure response to determine an oil well’s reservoir characteristics. The build-up test requires producing the well until a stabilized production rate and pressure is achieved, then shutting in the well for a period from 2 days up to 4 weeks. Often used as a tool to determine static bottom hole pressures, the AAWS test can help satisfy AER annual pool requirements.

Read more about Automated Acoustic Well Sounder.

Fluid Level Determination

With over 20 years of experience, SSI has become a known leader in identifying optimization opportunities in various artificial lift situations. Our state-of-the-art equipment and software can diagnose wellbore anomalies that could potentially be holes in tubing or possibly even wax build up. We go beyond a simple “fluid shot”.

Learn more about Fluid Level Determination.

Foam Depression Test

Foam depression testing ensures that fluid is held above the pump to eliminate gas lock or pump burnout. Calculating pump intake pressure is key for the inflow performance relationship. Knowing a trus gas/liquid interface helps optimization programs be effective and helps producers to make more revenue. Foam depressions are a simple method to identify optimization opportunities in a cost-effective way.

Discover more about our Foam Depression Test.

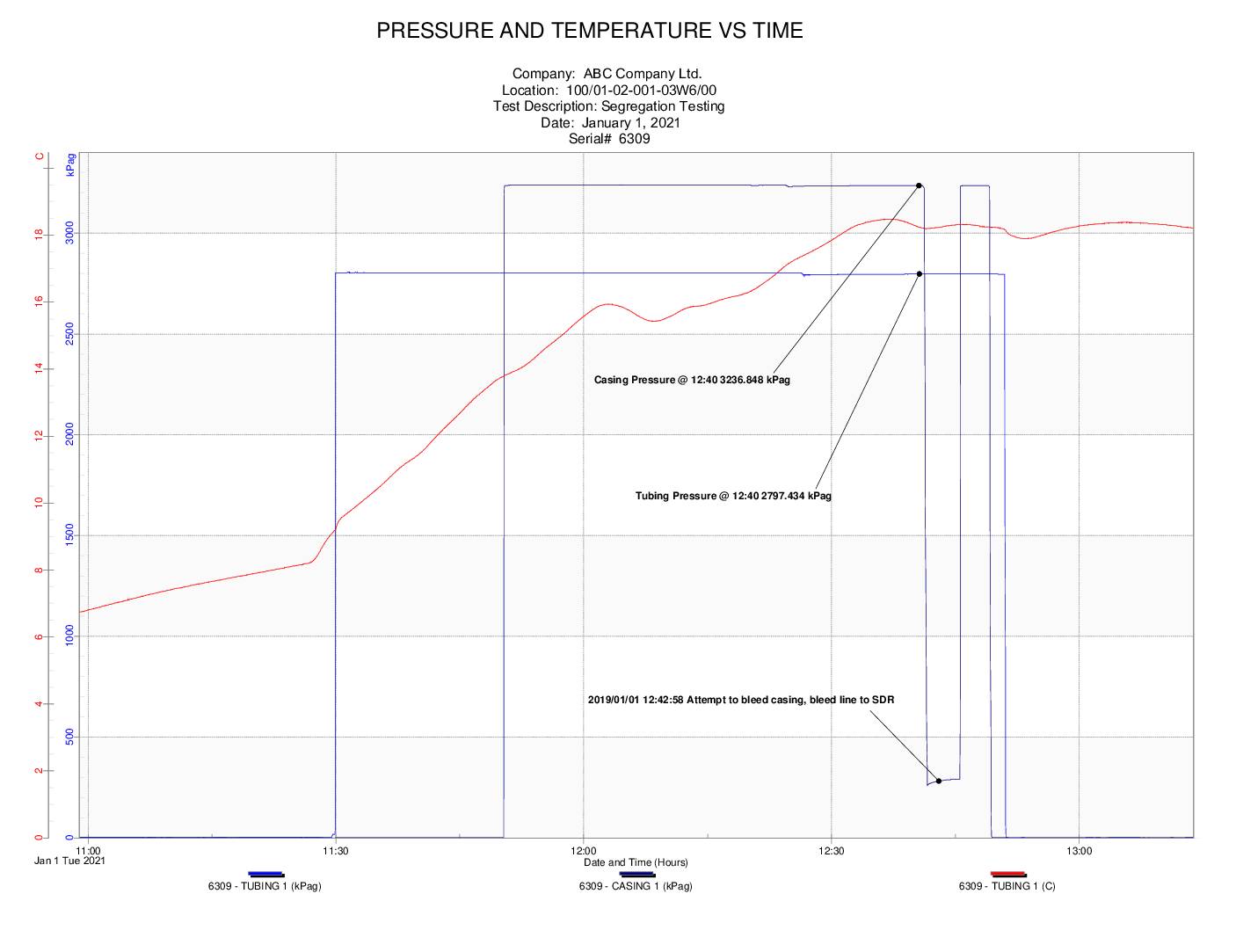

Segregation Testing

Segregation testing can confirm well segregation, as well as any well communication issues. SEGT can also prove packer isolation, identify holes in tubing, and prove that a sour zone does not co-mingle with a sweet zone.

Learn more about Segregation Testing in our Packer Isolation Testing information.

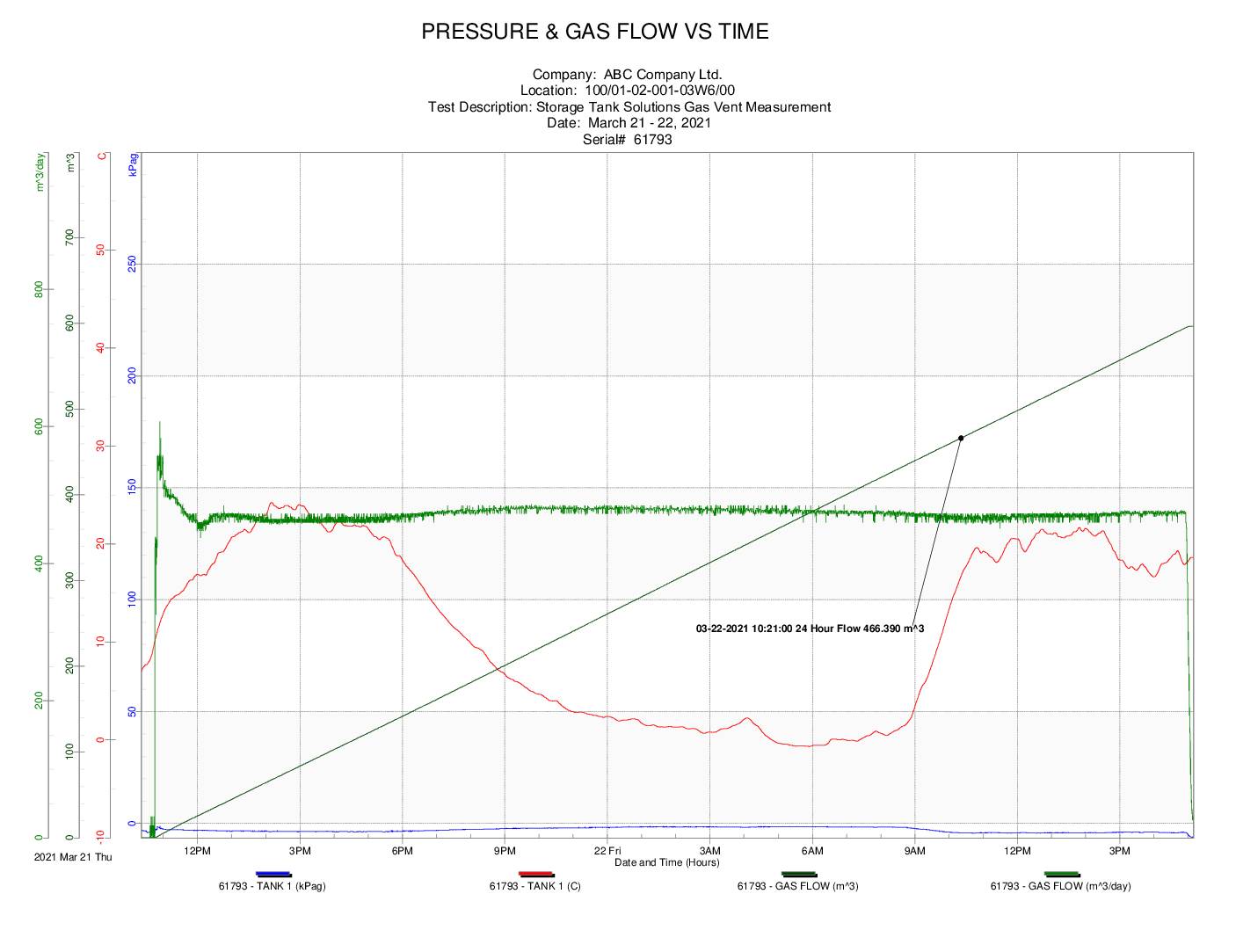

Pipeline Optimization

High accuracy and high resolution surface data can give a picture of what is happening and when it’s happening in their pipeline system. Pipeline operators struggle to define effective solutions to solve their slugging challenges. As a result, current market approaches tend to be reactive, developed by trial and error, leading to ultimately unsatisfactory solutions. There is an old saying; “timing is everything” – contact us to learn more about how effective implementation will cut your operational costs

Continue reading about our Pipeline Optimization.