Suspended Well Inspection

Verifying a suspended asset’s integrity when working in the oil and gas industry requires conscious attention to detail and industry-leading experience Surface Solutions’ 20+ years of experience brings to every job we do.

Every year, thousands of wells across Western Canada will be classified as suspended by being inactive, abandoned, or orphaned as part of the normal lifecycle of every well. Several tests are used by Surface Solutions’ to test a suspended well, including surface casing vent flow indication and gas migrations, as well as any pressure tests needed to ensure environmental diligence.

While these tests are designed for inactive, suspended, abandoned, or orphaned wells, operators can use the data derived from testing to inform them about their other oil and gas infrastructure, including pipelines and control sheds. As part of a well’s natural, inevitable lifecycle, it will move through the inactive and suspended classifications. Wells will then move through to being abandoned, reclaimed, orphaned, or back to producing to start the cycle again.

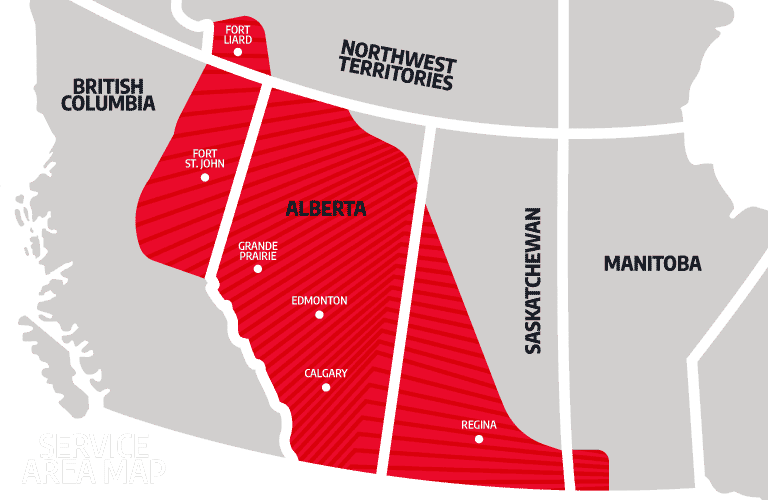

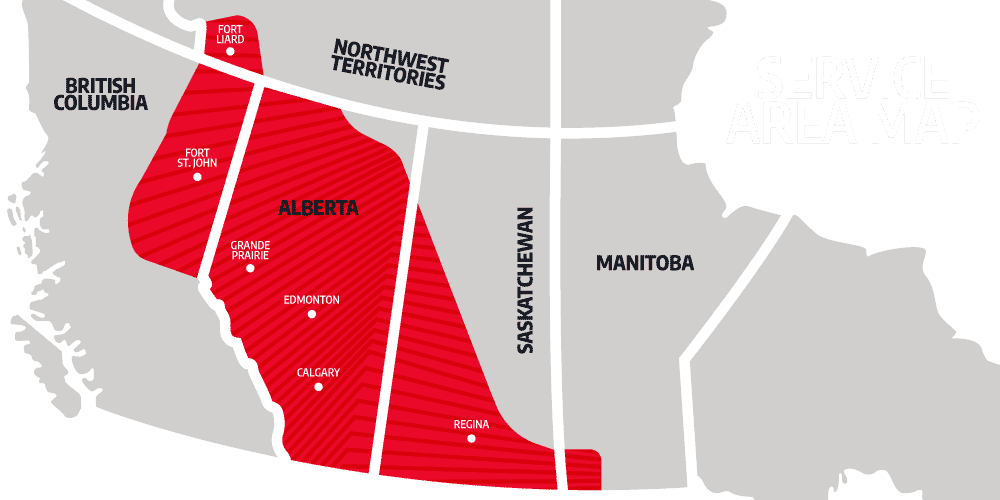

Surface Solutions works with our operators across Western Canada to fulfill each aspect of their region’s regulatory requirements for suspended well inspection. Surface Solutions’ regulatory testing services utilize our industry-leading technological advances in data acquisition to provide oil and gas customers with accurate, flexible, and affordable data. Surface Solutions’ business foundations are based on our experienced leadership and recognized customer service.

Our technical skills and knowledge base, along with our equipment, gives us highly sought-after services recognized by oil and gas leaders who trust us to do the job and to do the job well.

Safety And Regulatory Compliance

In the oil and gas industry, compromising on safety and regulatory compliance is not an option. Operators are constantly working on cutting costs and finding new, innovative ways to do the work and drive efficiency. Surface Solutions’ experts help operators navigate how to meet their regulatory and budget commitments in a regulatory landscape that continues to evolve, requiring companies to adjust their policies or implement new ones. This emphasis on efficiency is most notable for operators in Alberta, with the AER’s Inactive Well Compliance program that gives businesses a strict 5-year timeline to address any wells that are not compliant with AER Directive 013.

Due to their often logistically difficult locations, achieving regulatory compliance for many of these wells would require the costly building of roads and marshaling multitudes of equipment. All of which can have a huge impact on an operator’s budget.

Surface Solutions’ fully mobile, portable equipment allows us to continually innovate ways to approach the challenges in the oil and gas industry. By utilizing our industry-leading reporting database, Surface Solutions saves our customers time and money while managing their complete regulatory compliance testing needs.

Inspecting A Suspended Well

Designed to cut costs for our customers in mind, Surface Solutions’ logistics, evidence-driven planning turnkey reports put data in the hands of those making the decisions when they need it.

Outside of the cost-saving benefits of using Surface Solutions’ portable testing equipment for suspended well inspections, the overall process offers operators the ability to minimize their environmental impact, including reductions in the number of trees that need to be cleared and ground habitat disruption to build and access roads to the wells to be inspected.

Very little prep is needed at the lease for suspended wells inspections, which reduces the need for costly lead time to complete the work and allows for flexibility in scheduling, ultimately leading to cost savings.

Suspending A Well

Prior to a well being classified suspended, the well must first pass through an inactive phase for 6 to 12 months. An inactive well can not produce oil or gas, injected fluids, or disposed of waste, depending on the type of well and its potential risks to the public or environment. If the well meets this criterion for the entire 6 to 12 months, it is considered inactive.

To suspend the inactive well, an operator will contact Surface Solutions to perform a series of tests as part of a suspended well inspection per the region’s regulatory requirements. Procedures will be performed to ensure that the well poses no current or future risk to the public and the environment before being suspended. Requirements are set by the regulatory bodies to suspend wells and safely maintain them.

The suspended well must meet these requirements as long as the well is suspended, and wells can remain suspended until the operator determines that the well is no longer needed for energy development and can be abandoned.

For an inactive well not to be classified as suspended after 12 months, it must restart production, and the requirements for what classifies as production will vary with the type of infrastructure on the pad.