Completions

Data Acquisition

Founded in 1999, Surface Solutions Inc. has remained focused on complete and accurate oil and gas well optimization.

With technological advances in data acquisition, oil and gas producers are able to have test data that is flexible and affordable. SSI has built a solid foundation for business, based on leadership and excellent customer service.

Planning is key at SSI – by utilizing our database, we save you time and money while managing your complete completion needs.

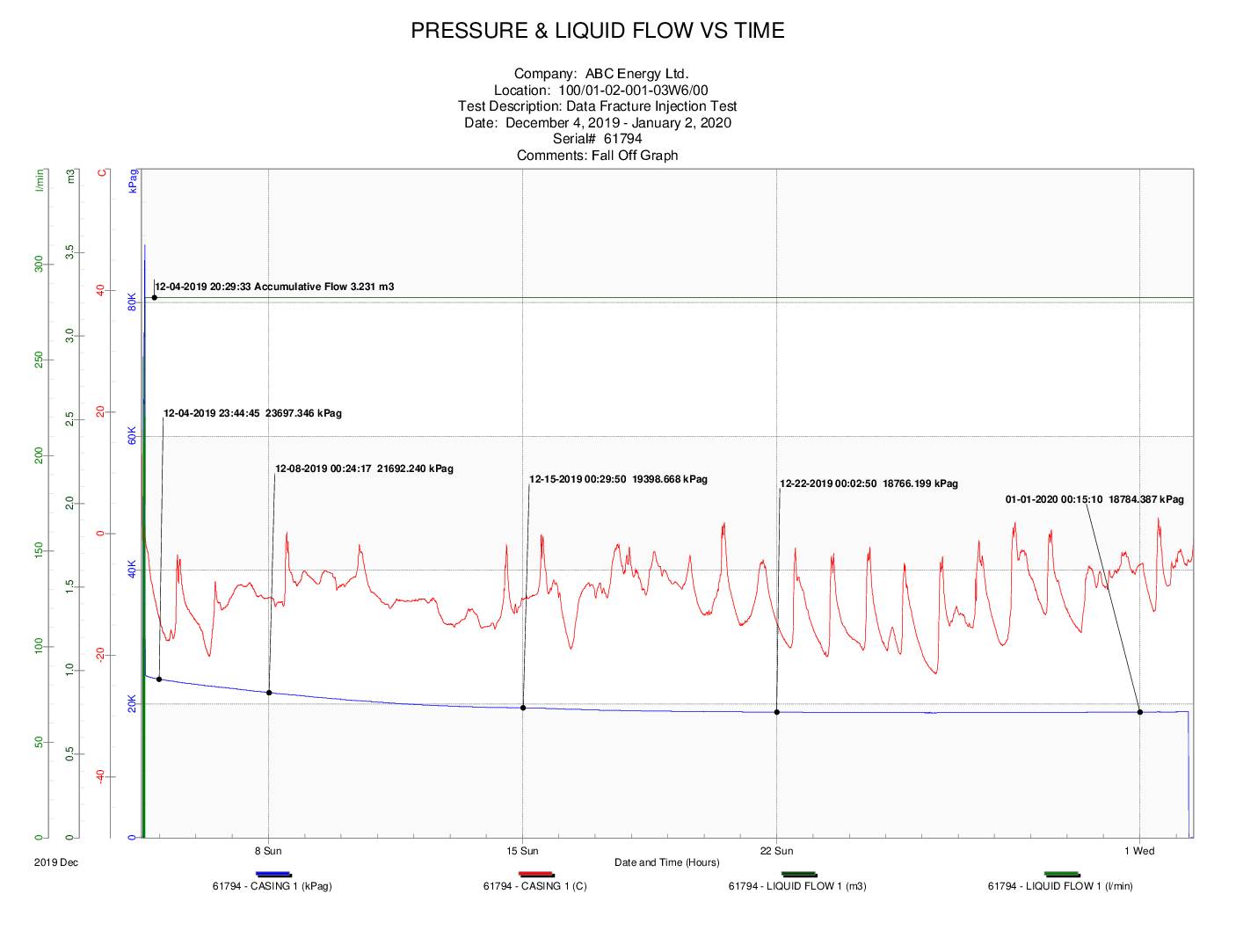

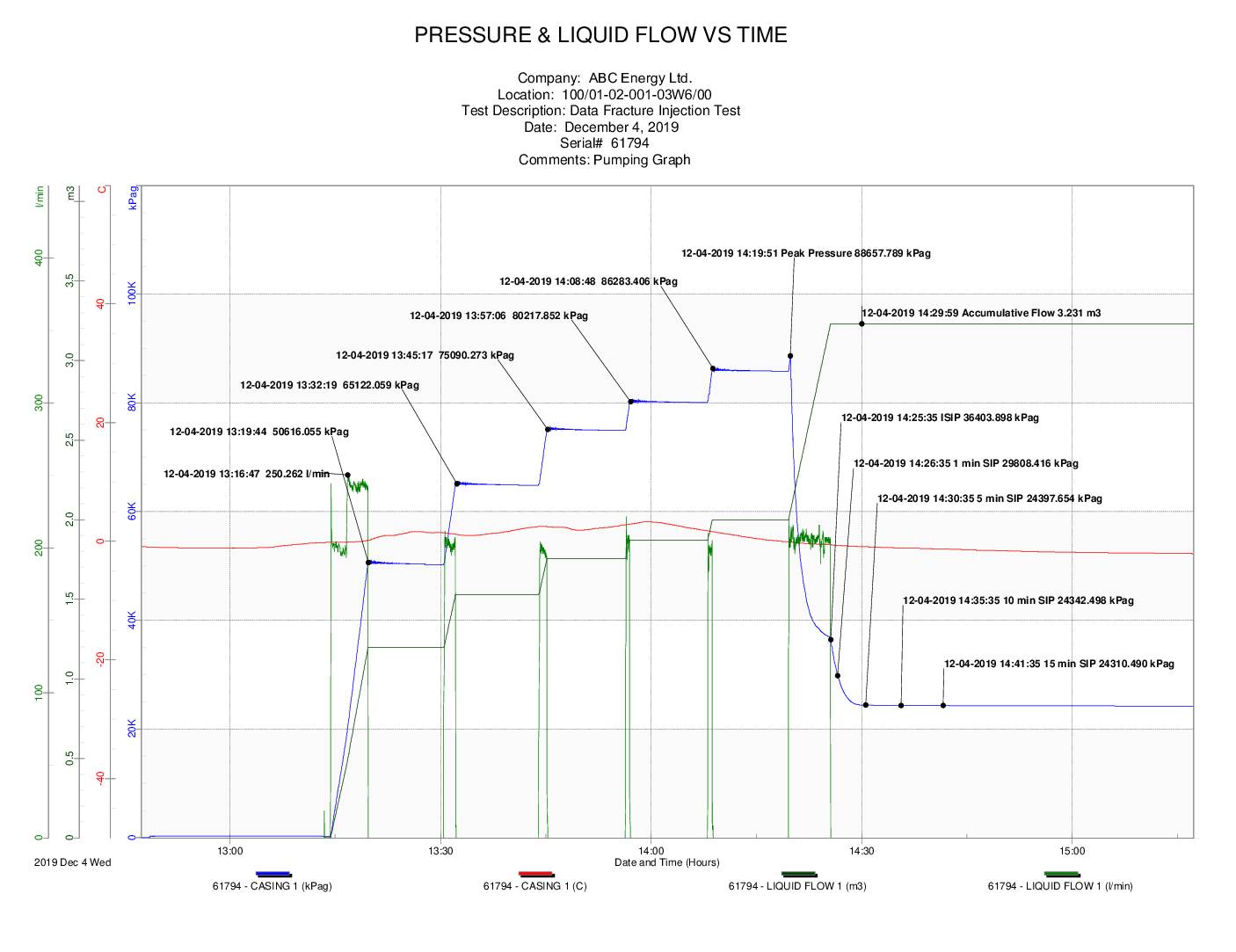

Data Fracture Injection Test

Data Fracture Injection Testing (DFIT) has become the most cost-effective way to satisfy AER initial conditions and helps to determine the permeability of a specific zone. SSI captures injection rates, volumes, and pressures as high as 15,000 psi, which is transmitted in real time to allow our clients to make decisions for completions immediately. SSI can also generate and submit pasfiles, as well as a full DFIT analysis, with the help of our alliance partner FracKnowledge.

Read more about our Data Fracture Injection Test.

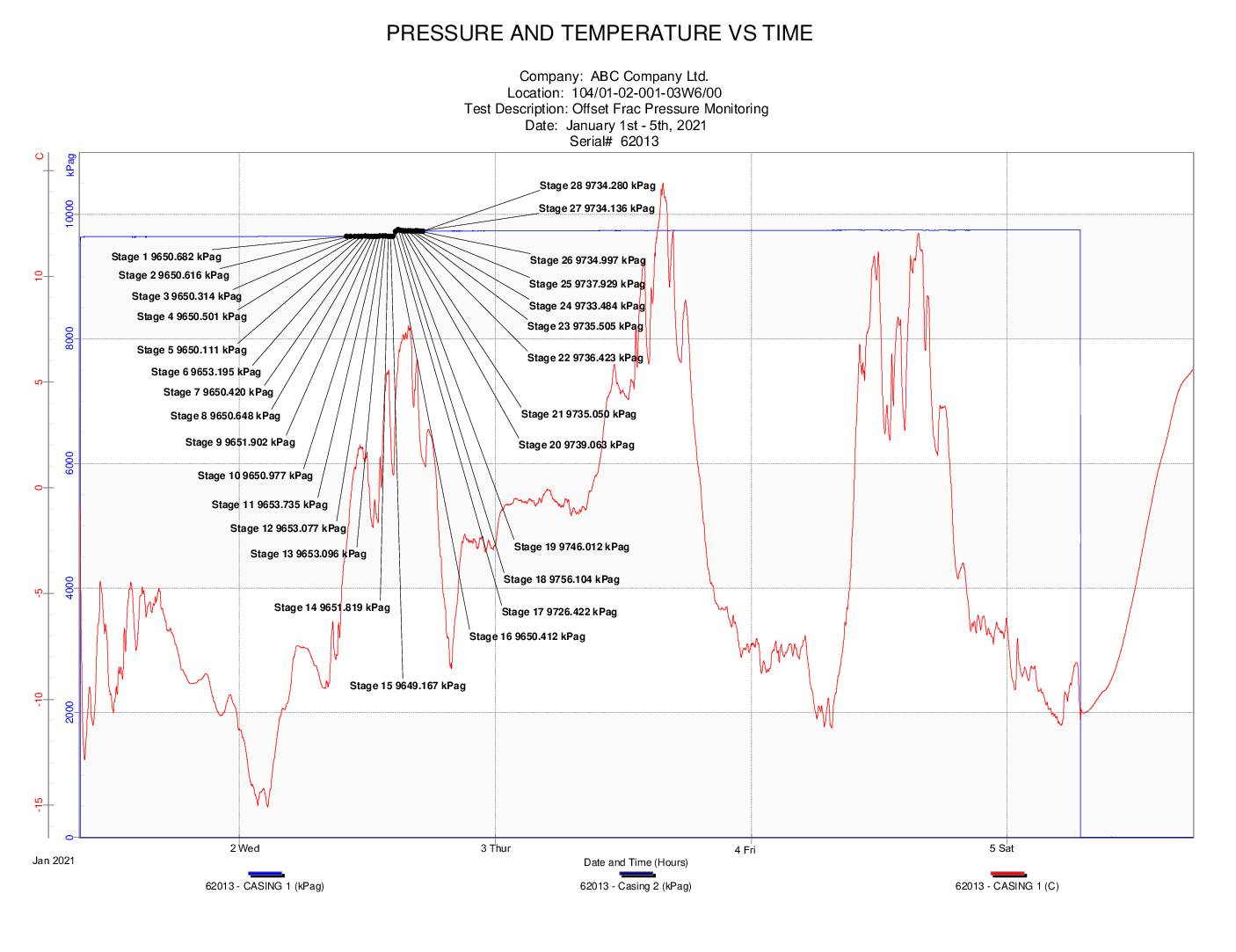

Offset Frac Monitoring

SSI is known for innovative equipment and safe work procedures that help producers comply with AER directive 83. Using our web-based multiwell pressure data, producers can see inter-well communication in real time. Decisions can be made on site or in the office to avert potential environmental disasters. Our data has helped to identify IOW production anomalies and lower remediation costs. SSI often follows our DFIT service with Offset Frac Monitoring equipment, helping logistics in the process. We provide Frac Planning maps to help identify competitor wells and suspended assets that may incur a frac hit.

Find out more about our Offset Frac Monitoring.

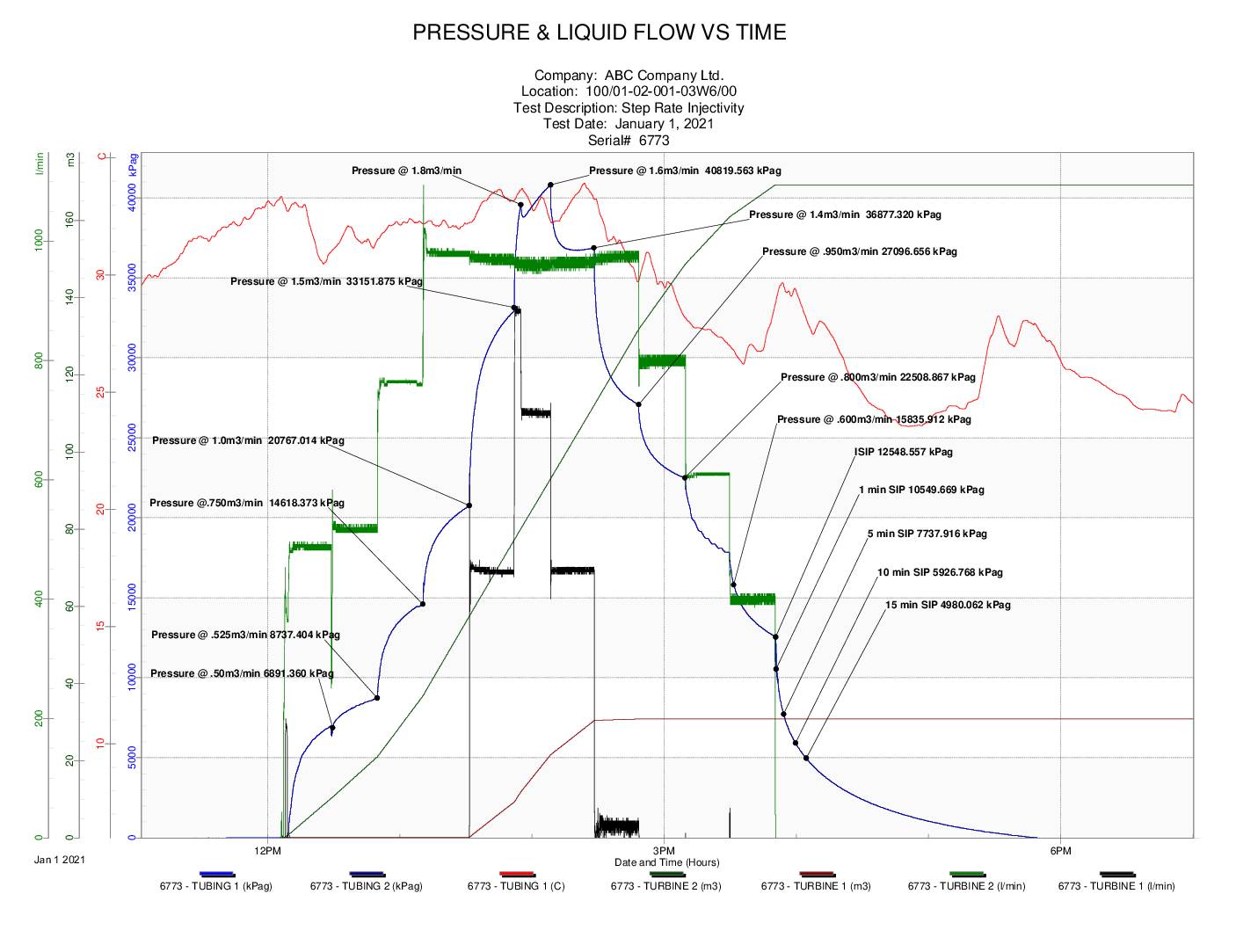

Step Rate Injectivity Test

Step rate testing determines the maximum wellhead injection pressure and rate to optimize potential zonal injection. Disposal wells and water flood programs use our high accuracy and high resolution equipment to ensure data quality is maintained. Our clients depend on SSI to satisfy AER directive 65 when submitting disposal well applications. When STEP tests are used in water flood schemes, real time interference testing can also be critical.

Find more information about our Step Rate Injectivity Test.

Perforation Inflow Testing

Perforation Inflow Tests are a type of closed chamber test that is conducted by allowing reservoir pressure into the closed wellbore. SSI uses real time surface data to monitor the ensuing pressure buildup with time. This occurs when the well has perforated in an under-balanced condition. These tests have been referenced as: Slug Tests, Surge Tests, Perforation Inflow Diagnostics (PID), or Closed Chamber Tests.

Perforation Inflow Tests are attractive in low permeability reservoirs because estimates of initial reservoir pressure (pi), permeability (k), and skin (s’) can be obtained in a shorter duration than buildup tests, with the added benefit that they don’t require any venting or flaring into the atmosphere. Learn more about our Perforation Inflow Testing.

Abandonment Vent Flow Testing

In accordance with AER directive 20, SSI performs in-depth gas flow detection that surpasses the mandated “bubble in a cup” vent flow determination. We strongly believe in datalogging the 10-minute vent flow determination – because of this, we use a patented technology to offer our clients the most accurate measurement. The flow test can be downloaded and sent to the regulator or head office to determine if a threshold limit should be applied.

Discover more information about our Abandonment Vent Flow Testing