Packer Isolation Testing

Packers are a valuable tool for oil and gas service providers to analyze borehole characteristics and confirm segregation between wellhead barriers and annular integrity. A pressure test of the tubing/casing annulus is designed to evaluate the integrity of the casing, tubing, and packer. A packer isolation test is successful when regulators apply and maintain the required pressure designated by regulators for a set time frame.

Packers can also determine water quality in discrete zones in both cased and uncased wells. Packers to determine the hydraulic characteristics of distinct zones within a borehole by sealing downhole pressures inside or outside the tubing string. Surface Solutions completes our field-proven packer isolation tests using a dual-channel, temperature-compensated pressure recorder.

As a result of their high-performance indicators, such as their degree of integration, pressure measurement accuracy, and real-time calibration, multi-channel pressure recorders are considered to be at the forefront of the measuring industry. These market-leading tools are key to confirming the segregation between wellhead barriers and annular integrity.

Surface Solutions completes packer tests by isolating specific sections of consolidated formations. Exhaustive borehole logging is paramount in visually pinpointing fractures and possible producing zones. A flow dispersal profile is completed to help distinguish flow patterns in the wells and determine the site of producing elements. This data is then used to select isolation points for a series of packer tests.

Packer tests give Surface Solutions’ customers a range of improved zonal isolation solutions for cased-hole completions. Our packers reliably isolate wellbore sections to lower well construction risks even in the most extreme downhole conditions.

Surface Solutions provides customers across Western Canada with best-in-class reports detailing casing integrity, wellhead seal, and packer integrity to pinpoint where an issue may occur.

Confirming Segregation And Annular Pressure

Well integrity issues are frequently non-singular and can manifest as multiple downhole challenges. The observed surface pressure results from communication from one annulus to another by a shallow casing leak. If an external leak is identified, it should be secured before isolating the source of produced fluids.

These leaks often result from galvanic corrosion or oxidation of tubular. Sealing the casing leak helps prevent the unwanted displacement of large and wasted volumes of resin into the tubular leak path to seal the source. With proper volumetric displacement, the casing leak is solved first, and then the channel or micro-annuli responsible for pressure transmission can be properly sealed.

Surface Solutions provides customers with best-in-class reports detailing casing integrity, wellhead seal, and packer integrity to pinpoint where a leak may occur.

Oil And Gas Regulator Guidelines

As the injunctions placed by the government on the oil and gas industry, the private sector, and environmental groups increase, it is important to ensure operations are current and meet the ever-changing regulatory guidelines.

Surface Solutions’ experts can create individualized packer testing programs to satisfy each regulator’s requests and work with operators to achieve government approval. Properly written programs continually achieve the highest quality of testing results when testing for the casing, tubing, and packer integrity. Our tests’ superior data all starts with our temperature-compensated pressure recorders.

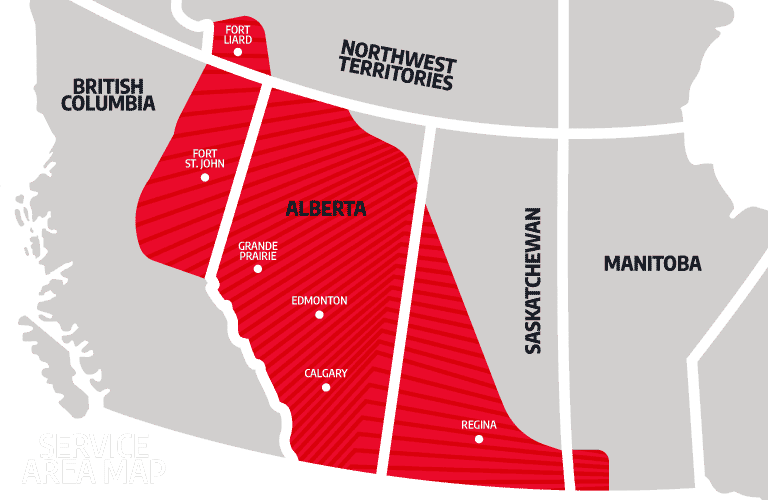

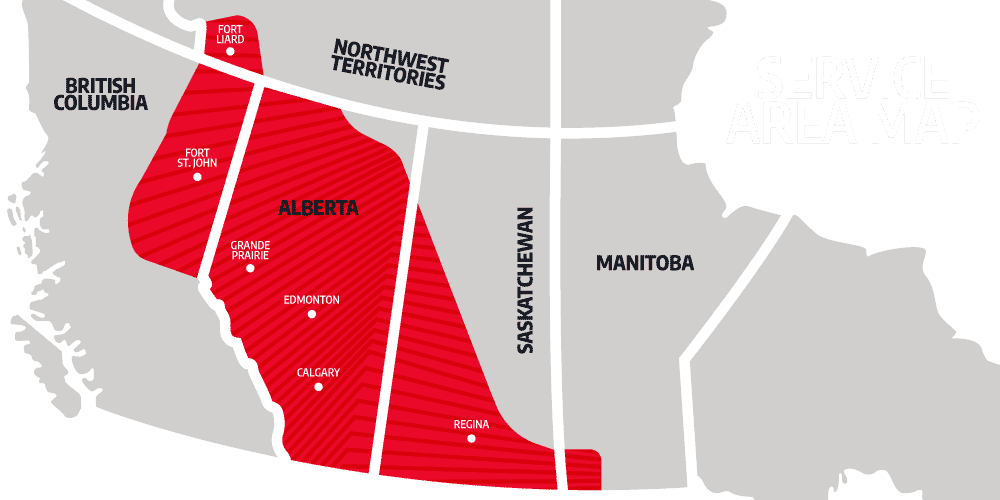

Surface Solutions provides a range of wellsite services and tests to maintain compliance within the parameters set out by the Alberta Energy Regulator (AER), Saskatchewan Ministry of Energy and Resources (SMER), BC Oil and Gas Commission (BCOGC), and other regulatory agencies. Typically these services are conducted annually, reported, and submitted to the local regulatory agencies.

All Surface Solutions’ equipment is designed to be modular and portable, making our routine inspection and compliance services safe, cost-effective, dependable, and executable in all locations.

Alternative To A Packer Isolation Test

Instead of a standard packer isolation test, Surface Solutions’ can perform Alberta Energy Regulator segregation tests that will satisfy the Digital Data Submission submission system.

Segregation testing (SGT) can confirm well segregation and well communication issues. Segregation confirms the confinement of each fluid in a well to its proper pool or flow channel so that it is separate from the fluid in or passing from or to any other pool. Segregation testing can also be used to prove packer isolation, identify holes in the tubing, stuck plungers, tight spots or restrictions, gas analysis, optimization run times, and provide data that can be used to verify that a sour zone does not co-mingle with a sweet zone.

Annual tests conducted by Surface Solutions’ experts can also confirm that segregation is maintained between the injection fluid and the annulus at all fluid injection and disposal wells.

Correct segregation is a key issue affecting handling systems today. Responsible for significant production loss in the oil and gas industry, including downtime. Understanding the role of segregation in processing is critical to proper operation and reliable production.