Data Fracture Injection Testing

Data Fracture Injection Testing (DFIT) is the industry standard for creating an analyzable pressure-decline response and deriving the minimum horizontal stress through fracture-closure identification. DFITs are reliable and cost-effective techniques to satisfy Alberta Energy Regulator’s (AER) initial conditions and help determine a specific zone’s permeability.

During a DFIT, test fluids are pumped in short bursts into a reservoir to create a small fracture that cuts through wellbore damage. Hydraulic fractures will naturally follow the path of least resistance, forming perpendicular to the formation’s minimum principal stress, often referred to as the “closure stress” or “closure pressure.”

A clear indication of breakdown during the pump-in is necessary, and the injection rate and volume are recorded for evaluation. After the procedure, the pressure is allowed to decline and recorded. Pressure data can be examined to determine when the fracture closes. The pressure a hydraulic fracture closes at is equivalent to the formation’s smallest principal in situ stress (present-day active natural stresses).

Surface Solutions believes that a single unique closure event can satisfy numerous diagnostic plots when we detect the fracture closure. A consistent interpretation of fracture closure can be determined when different analytical methods are used.

Safety is a core value of every member of the Surface Solutions team. We understand that while a massive amount of information could be derived from these tests, prior knowledge about the formation and the expected fracture profile is key to the safe and successful completion of any data fracture injection testing project.

What is DFIT?

Diagnostic fracture injection testing (DFIT), also called mini-frac, mini fall-off, or data frac, is a pressure transient test conducted for ultra-low permeability shales to provide valuable information about the reservoir and hydraulic fracture treatment parameters.

Tight formations evaluation using classical well-testing methods are generally not practical as it would require a long period of shut-in time, months or even years, to reach the proper flow regime to gather meaningful information.

DFIT has become a commonly used method to evaluate reservoir and hydraulic fracture characteristics in conventional and unconventional reservoirs in the oil and gas industry.

Surface Solutions DFIT Applications

For many applications, especially cyclic steam stimulation (CSS), steam-assisted gravity drainage (SAGD), and water or polymer flood operations, the minimum in situ stress controls the maximum operating injection pressure to sidestep, fracturing the cap rock.

Surface Solutions continually ensures that our in situ operations comply with approved conditions under the Environmental Protection and Enhancement Act (EPEA), which supports the protection, enhancement, and use of the environment, including air, water, soil, wetlands, and wildlife.

Surface Solutions captures injection rates, volumes, and pressures as high as 15,000 psi, transmitted in real-time, allowing our clients to make decisions for completions immediately. Surface Solutions can also generate and submit pasfiles and a full DFIT analysis with the help of our alliance partner FracKnowledge.

DFITs are mandatory under Alberta Energy Regulator’s requirements for any new or expansion projects.

DFIT Data Solutions

Surface Solutions can perform both cased-hole DFIT and open-hole, with and without frac-flowback. To ensure the quality of data obtained, multiple points of high-precision measurements are recorded at the wellhead and downhole with backups.

Surface Solutions was the first oil and gas optimization company to live stream web-based results where test data can be viewed in real-time through the internet as it is acquired in the field. We continue leading industry reporting through new technologies and utilize an extensive cloud-based data system to store all test history.

From gas migration testing, packer isolation testing, suspended well inspection, surface casing vent flow testing, and pipeline integrity testing, our comprehensive and customizable service model offers the utmost flexibility for our clients.

DFIT Flowback Analysis

Frac-flowback is the recovery of fluid used in the high-pressure hydraulic fracturing process to stimulate oil and gas production in a well. Typically, formation water, oil, and gas are recovered along with the frac-flowback fluid.

Surface Solutions offers experienced, professional personnel and highly-specialized equipment to safely meet every production testing and flowback (well testing) requirement. Our robust DFIT Flowback Analysis (FBA) provides the information our clients need to make decisions about their business when it matters most.

Our equipment and well-trained personnel can safely operate in all flowback/production testing environments, including high-risk environments, e.g., high temperature, high pressure, and high concentrations of Hydrogen Sulfide (H2S or sour gas).

Surface Solutions Commitment To Safety

Surface Solutions is accountable for creating worksites where our employees can perform their work without the risk of health hazards.

Our employees adopt different procedures or increase their protective equipment for safety through peer-shadowing before exposure to any new task solo. The Surface Solutions teams take a proactive approach to seek out potential health hazards found in the workplace and encourage feedback from our employees with their boots on the ground.

At Surface Solutions, we’re committed to anticipating, recognizing, evaluating, and controlling workplace environmental and health hazards that may cause illness or impair the well-being of our employees, contractors, or the community members who live or work near our operations. Any incidents associated with the failure of systems, equipment, or mechanical integrity can negatively impact worker safety and the environment, which is why we enforced exhaustive process safety practices to mitigate these risks.

Contact Surface Solutions For Your Data Fracture Injection Requirements

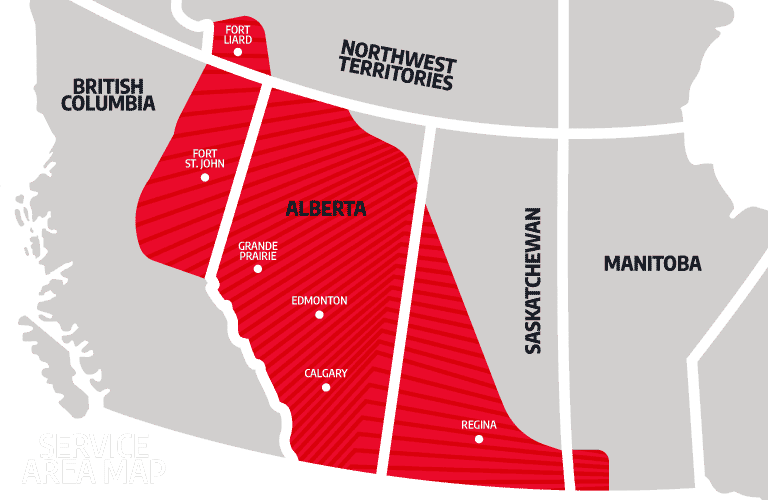

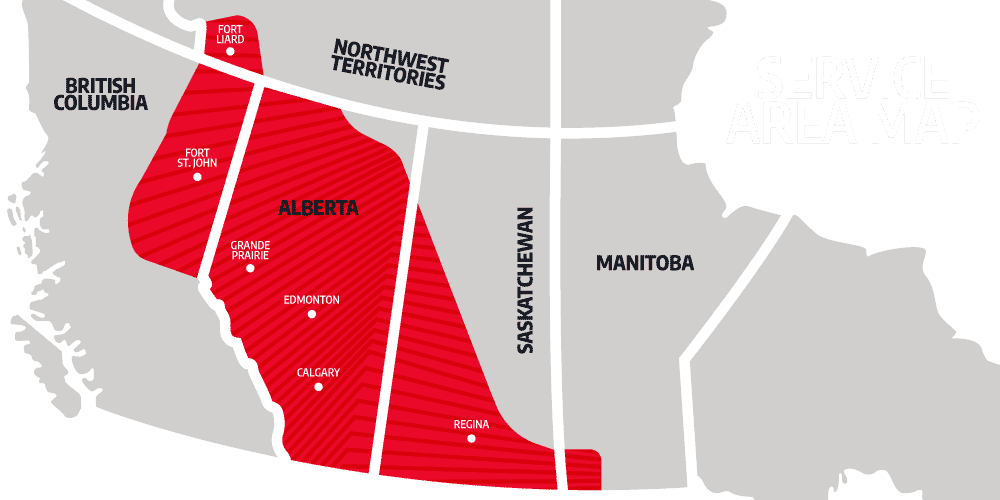

Surface Solutions provides Completions Services, including DFIT solutions, across Canada. We are the industry standard for your completions services needs.

Call us at 780-538-1074 or visit our Contact page for more information.