Surface Casing Vent Flow Test

The Canadian government is working to reduce global methane emissions by 45 % from the oil and gas sector by 2025. Surface Solutions understands that achieving this goal realistically requires operators to have digital access to data and tools to identify the major sources of emissions within the oil and gas industry.

Fugitive emissions account for nearly half of Alberta’s methane gas emissions from oil and gas activities in Western Canada. Surface casing vent flow (SCVF) leaks are the largest contributors to fugitive emissions. Surface casing vent flow (SCVF) and the subsequent gas migration can cause several issues, including interruption of production, possible water contamination, greenhouse gas emissions, fire hazards, or damage to the operator’s reputation.

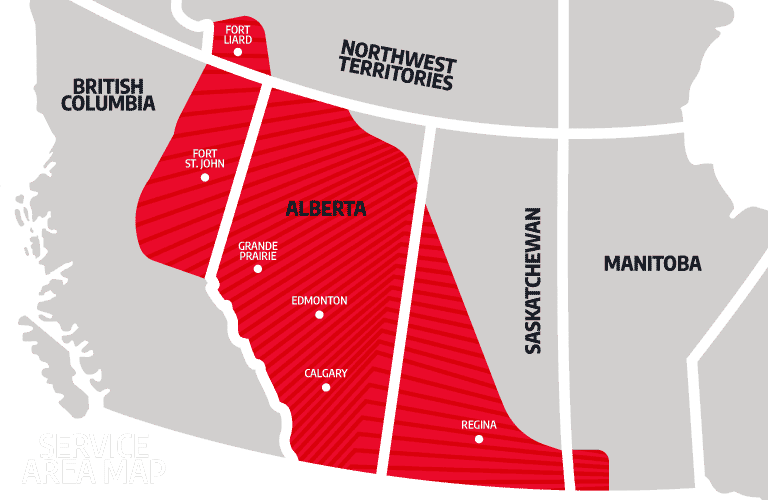

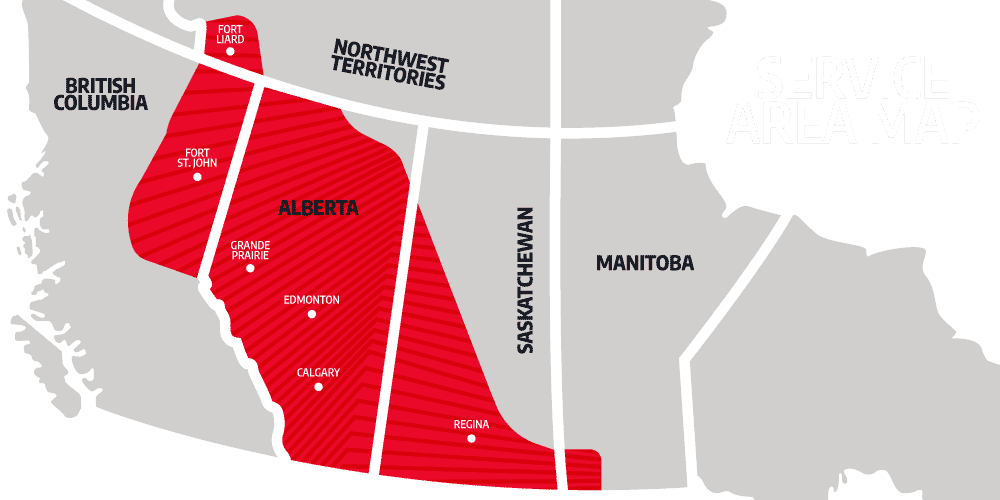

The emissions requirements set by regulatory agencies in Alberta, British Columbia, and Saskatchewan have seen significant technological growth in how surface casing vent flow testing data, also called a “Bubble Test,” is reported. Test results are logged in Surface Solutions’ industry-leading report format that can be submitted to the DDS Portal or eSubmissions.

Digitized Gas Flow Testing

Surface casing vent flow is a phenomenon that refers to an uncontrolled flow of formation gas or fluid through the surface casing vent assembly on a wellhead. Surface casing vent flows may be caused by several factors ranging from an insufficient cement seal or a downhole component’s failure to allow downhole hydrocarbon migration.

Surface Solutions is a leader in digitized gas flow that can be audited by regulators such as the AER. Our in-house water analysis helps operators reduce the total turnaround time and lab costs associated with a liquid surface casing vent flow test. With a remarkable track record in the oil and gas industry for being the premiere service provider for carbon isotone sampling, Surface Solutions’ provides stakeholders with accurate, timely data allowing operators to make key decisions to be made when a well is abandoned in its lifecycle.

Surface Solutions works with our operators across Western Canada to fulfill each aspect of their region’s regulatory requirements for surface casing vent flow testing. Surface Solutions’ regulatory testing services utilize our industry-leading technological advances in data acquisition to provide oil and gas customers with precise, flexible, and inexpensive data.

Our technical skills and knowledge base, along with our equipment, gives us highly sought-after services recognized by oil and gas leaders who trust us to do the job and to do the job well.

Permanent Cement Seals

Cementing forms a permanent seal between the casing and the borehole wall. Good mud displacement practices help avoid mud channels in the cemented annulus, which will help prevent gas flow and can aid in attaining better cement bonds. Other factors affecting displacement efficiency and hole cleaning include centralization, pipe movement, spacer or preflush design, cement system selection, and displacement rates.

When detected, repairing a surface casing vent flow or gas migration can be extremely difficult due to other potential hidden or unknown sources of gas that may be communicating with the existing channels. Complications can arise, including multiple gas sources, improper placement techniques, or non-ideal cement systems. Additional complications can result in reduced success rates, generating additional costs for the client and sometimes leading to secondary job failures.

If a test results in a positive surface casing vent flow on the backside of the inner casing, it can indicate fluid or gas migration and movement within the annulus. At the same time, the cause of the movement can be the result of multiple sources and factors that are difficult to identify accurately. Substantial time and effort might be required to identify all the sources producing the migration.

Portable Testing Equipment

Due to their often logistically difficult and remote locations, achieving regulatory compliance and performing proper surface casing vent flow tests for most wells would require building roads and utilizing large equipment to access them. Outside of the significant increase in cost, the additional time added to the timeline to safely access the well sites is often a deterrent to operators properly performing these tests.

In a wellbore’s life, cement sheath damage can occur during cement placement, completion activities, well work-over operations, or production. With this in mind, Surface Solutions’ experts work with operators to meet the regulatory requirements from the beginning of the well planning stage to ensure formation isolation is achieved.

Surface Solutions’ fully mobile, portable equipment allows us to continually innovate ways to approach the challenges in the oil and gas industry in Western Canada. Real-time surface casing vent flow equipment can be installed on the subject well to identify internal gas migration to the surface. Surface Solutions’ industry-leading report format can be submitted directly to the DDS portal or eSubmissions. By utilizing our industry-leading reporting database, Surface Solutions saves our customers time and money while managing their complete regulatory compliance testing needs.